PRODUCT PARAMETERS

Description

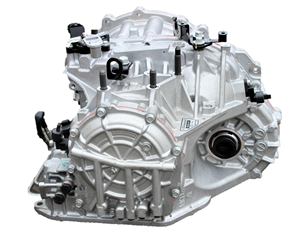

Introduction of TQG High Rigidity Zero Backlash Gearbox Reducer CSF 14 Harmonic Drive Gear for Robot Arm Joint

TQG High Rigidity Zero Backlash Gearbox Reducer CSF 14 Harmonic Drive Gear for Robot Arm Joint, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.TQG High Rigidity Zero Backlash Gearbox Reducer CSF 14 Harmonic Drive Gear for Robot Arm Joint is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of TQG High Rigidity Zero Backlash Gearbox Reducer CSF 14 Harmonic Drive Gear for Robot Arm Joint

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(TQG High Rigidity Zero Backlash Gearbox Reducer CSF 14 Harmonic Drive Gear for Robot Arm Joint)

Specification of TQG High Rigidity Zero Backlash Gearbox Reducer CSF 14 Harmonic Drive Gear for Robot Arm Joint

The TQG High Rigidity No Backlash Transmission Reducer CSF 14 Harmonic Drive Equipment is a precision-engineered element developed for high-performance robot applications, particularly in robot arm joints calling for exceptional precision, durability, and dynamic action. This harmonic drive gearbox features a small, lightweight layout enhanced for seamless assimilation right into robot systems while supplying unparalleled torque transmission and positional accuracy. Its core innovation relies on harmonic drive principles, using a flexible spline, wave generator, and circular spline to attain zero-backlash procedure– ensuring specific movement control and repeatability in demanding commercial, medical, or aerospace settings.

The CSF 14 model boasts a high strength framework, lessening torsional deflection under tons to keep precision even in high-torque scenarios. Key requirements include a rated torque of 14 Nm (continuous) and an optimum peak torque of 42 Nm, allowing reliable performance in vibrant robot motions. The reduction ratio choices range from 30:1 to 160:1, catering to varied speed and torque requirements. With a placing accuracy of ≤ 1 arcmin and repeatability of ≤ 0.1 arcmin, it ensures ultra-precise control for tasks like setting up, welding, or medical robotics.

Built from high-strength alloy steel and precision-machined elements, the transmission is developed for long life and resistance to wear. It runs successfully within a temperature level series of -10 ° C to +80 ° C and supports bidirectional rotation. The input interface works with common servo motors, while the output flange is customizable for integration with robotic arm links. Its IP65-rated real estate supplies security against dust and wetness, making sure dependability in harsh atmospheres.

Evaluating approximately 0.8 kg, the CSF 14 reduces inertial tons on robot joints, improving energy efficiency and motion dexterity. The maintenance-free design eliminates the demand for lubrication, reducing downtime. Applications consist of industrial robot arms, collaborative robots (cobots), CNC machinery, and automated guided automobiles (AGVs). By incorporating zero backlash, high torsional rigidity, and small measurements, this harmonic drive gearbox is an optimal option for engineers seeking to enhance accuracy, speed, and reliability in advanced robot systems.

(TQG High Rigidity Zero Backlash Gearbox Reducer CSF 14 Harmonic Drive Gear for Robot Arm Joint)

Applications of TQG High Rigidity Zero Backlash Gearbox Reducer CSF 14 Harmonic Drive Gear for Robot Arm Joint

The TQG High Rigidness No Backlash Gearbox Reducer CSF 14 Harmonic Drive Gear is a precision-engineered part developed for demanding applications in robot systems, particularly in robot arm joints. Its advanced harmonic drive modern technology makes sure exceptional performance in environments calling for high precision, repeatability, and integrity. With zero backlash and high torsional rigidness, this gearbox decreases positional errors, making it optimal for jobs where precision is critical, such as commercial automation, clinical robotics, and aerospace assembly.

The CSF 14 Harmonic Drive masters robotic arm joints as a result of its portable, lightweight layout, which optimizes space use without compromising load-bearing ability. Its high rigidness makes sure minimal deformation under heavy lots or sudden torque changes, keeping alignment and stability in dynamic operations. This is important for applications like CNC equipment, semiconductor manufacturing, and collaborative robots (cobots) where smooth movement and exact control are non-negotiable.

Secret advantages include its capacity to deal with high torque densities while operating at high reduction ratios (usually 30:1 to 160:1), enabling specific speed control and force transmission. The zero-backlash design gets rid of play between gears, making sure immediate action to input commands– an essential function for real-time changes in robotic arms utilized for welding, pick-and-place, or procedures. Furthermore, the CSF 14’s hermetic sealing safeguards inner parts from dirt, moisture, and contaminants, expanding life span in extreme commercial atmospheres.

This gearbox works with servo electric motors and incorporates perfectly right into robot systems, reducing power consumption and heat generation due to its high mechanical effectiveness (up to 85%). Its resilience and low maintenance demands make it an affordable solution for high-cycle applications. Industries such as auto manufacturing, logistics automation, and precision instrumentation benefit from its reliability and capability to maintain precision over numerous cycles.

In summary, the TQG CSF 14 Harmonic Drive Equipment is a keystone for innovative robotics, offering unrivaled accuracy, strength, and longevity. Its layout addresses the core obstacles of contemporary automation, making it possible for quicker, more secure, and a lot more reliable robot procedures throughout varied sectors.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of TQG High Rigidity Zero Backlash Gearbox Reducer CSF 14 Harmonic Drive Gear for Robot Arm Joint

What is a harmonic drive gear, and how does the TQG CSF 14 model work? A harmonic drive gear is a compact, high-precision gear system that uses flexible splines to achieve motion control with zero backlash. The TQG CSF 14 Harmonic Drive Gear utilizes this technology, combining a wave generator, flex spline, and circular spline to transmit torque smoothly. Its unique design eliminates mechanical play between gears, ensuring precise positioning and high rigidity, making it ideal for robotic applications requiring accuracy and repeatability.

Why is zero backlash critical for robot arm joints? Zero backlash ensures there is no lost motion between input and output gears, which is vital for maintaining positional accuracy in robotic arms. Even minor backlash can lead to cumulative errors in tasks like assembly, welding, or surgery. The TQG CSF 14’s zero-backlash design guarantees consistent performance, reducing calibration needs and enhancing repeatability in high-precision automation or sensitive environments like medical robotics.

What applications is the TQG CSF 14 best suited for? This gearbox is designed for high-torque, precision-driven robotic systems, including industrial robot arms (e.g., SCARA or articulated robots), CNC machinery, aerospace actuators, and medical robotic joints. Its compact size, high rigidity, and zero backlash make it ideal for space-constrained installations requiring reliable motion control under dynamic loads.

How durable is the TQG CSF 14, and what maintenance does it require? Built with high-quality materials like alloy steel and advanced lubrication, the CSF 14 offers extended service life even under continuous operation. It requires minimal maintenance—primarily periodic lubrication and routine inspections for wear. Its sealed design protects against contaminants, making it suitable for harsh industrial environments.

What factors should I consider when integrating the TQG CSF 14 into a robot arm? Key factors include torque capacity, speed requirements, mounting dimensions, and input/output compatibility. Ensure the gearbox’s rated torque and speed align with the robot arm’s operational demands. Verify the mounting interface matches your motor and joint design. Consult the manufacturer’s specs for temperature limits, inertia matching, and load directions to optimize performance and longevity.

(TQG High Rigidity Zero Backlash Gearbox Reducer CSF 14 Harmonic Drive Gear for Robot Arm Joint)

REQUEST A QUOTE

RELATED PRODUCTS

FAST small gearbox large truck Gearbox truck Gearbox 12JS180T

T Series 90 Degree gearbox Spiral Bevel Gears Bevel gearbox Spiral Spiral 1 1 Ratio Bevel 90 Degree gearbox Compact Small

0.06-15KW high efficiency R series screw reducer gearbox with motor flange can be used for industrial cement mixing

cycloidal gearbox BLD Series Cycloid Reducer Mechanical Equipment Transmission Vertical Cycloid Reducer

KL016004 New Gearbox Core Component for Container Lifting Transport System in Manufacturing Plants Material Handling Equipment