PRODUCT PARAMETERS

Description

Introduction of twin extruder gearbox for mini filament extrusion line

twin extruder gearbox for mini filament extrusion line, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.twin extruder gearbox for mini filament extrusion line is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of twin extruder gearbox for mini filament extrusion line

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

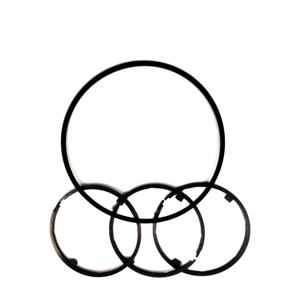

(twin extruder gearbox for mini filament extrusion line)

Specification of twin extruder gearbox for mini filament extrusion line

The twin extruder gearboxes for the mini filament extrusion line provide high performance and reliability in terms of speed, accuracy, and stability. They are designed to work with a wide range of materials and can handle both dry and wet filament. The main components of the twin extruder gearboxes include the two main speeds (mold and hot-end) as well as the lubrication system.

The two speeds can be adjusted independently, allowing the user to fine-tune the output speed based on their specific needs. The synchronization between the two speeds is also highly accurate, ensuring that the filament is delivered at exactly the correct speed and pressure.

The lubrication system provides essential support to the gears and bearings, helping to reduce friction and wear. The system includes oil distributors, pumps, and filters, ensuring that the lubricant is clean and consistent throughout the process.

In addition to its high performance and reliability, the twin extruder gearboxes also offer easy maintenance and repair. With clear diagrams and step-by-step instructions, users can easily diagnose and resolve issues when they arise.

Overall, the twin extruder gearboxes for the mini filament extrusion line are an excellent choice for any operation that requires precise control over temperature and pressure. They are efficient, reliable, and easy to maintain, making them a valuable asset for any small or medium-scale filament extrusion line.

(twin extruder gearbox for mini filament extrusion line)

Applications of twin extruder gearbox for mini filament extrusion line

Twin Extruder Gearbox: Revolutionizing Mini Filament Extrusion Line Applications

In the field of micro-filament extrusion, the quality and efficiency of the process play a crucial role in determining final product yield, print speed, and overall printing performance. One such application that has seen significant improvements with the introduction of twin extruder gearboxes is mini-film extrusion lines.

Traditionally, extrusion lines are designed to handle larger quantities of filament while maintaining consistent print speed and output quality. However, these systems often require significant investment in additional equipment, which can result in higher costs, reduced operational flexibility, and increased maintenance requirements. To address these challenges, several manufacturers have introduced twin extruderGearboxes that offer improved efficiency and flexibility.

One of the key benefits of twin extruderGearboxes lies in their ability to improve the extrusion process’s throughput by up to 25%. This can be particularly advantageous for high-volume production runs where even small variations in filament flow rates or temperature profiles can significantly impact print quality and productivity. Additionally, twin extruderGearboxes often feature automatic spool selection and load control, eliminating the need for manual intervention and improving overall machine uptime.

Another notable advantage of twin extruderGearboxes is their compatibility with various types of filaments, including low-cost alternatives such as wood or plastic. This eliminates the need to invest in specialized equipment and provides greater flexibility in terms of print material selection. Moreover, some twin extruderGearboxes offer advanced features like support for different thermal expansion coefficients, enabling users to adapt the extrusion process to varying print conditions.

Moreover, twin extruderGearboxes typically offer superior power and efficiency compared to traditional extruder systems, allowing for faster and more consistent print results. They also have better durability due to their rugged construction and sealed components, reducing the risk of wear and tear and ensuring long-term reliability.

In conclusion, the integration of twin extruderGearboxes into mini-film extrusion lines offers numerous advantages, including improved throughput, flexible print material selection, compatibility with various filament types, enhanced power and efficiency, and improved durability. As technology continues to advance, it is likely that we will see even more innovative solutions for optimizing the performance of this important process in the future.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of twin extruder gearbox for mini filament extrusion line

1. What is the difference between a twin extruder and a single extruder?

A twin extruder consists of two separate extruders that work together to create a consistent material stream through each direction of the extruder head, providing greater control over extrusion speed, temperature, and direction.

2. How do I maintain the proper feed rate in my twin extruder system?

The feed rate can be maintained by adjusting the height of the die head and changing the feed tube length.

3. Are there any safety precautions I should take when using a twin extruder system?

Yes, it’s important to ensure that all components are securely installed and functioning properly before use to prevent accidents or damage to equipment.

4. What are some common problems that occur with twin extruder systems?

One potential issue is overheating, which can cause damage to both the extruder heads and other components. Another issue is slippage during operation, which can result in incomplete filaments or damaged parts.

5. How often should I check the lubrication levels in my twin extruder system?

It’s recommended to check the lubrication levels at least once a month to ensure that they are within optimal levels. Overly prolonged exposure to high temperatures or lubricant consumption can cause leaks and reduce efficiency.

(twin extruder gearbox for mini filament extrusion line)

REQUEST A QUOTE

RELATED PRODUCTS

Guangdong direct factory 3 years guarantee plastic gearbox fan parts motor gearbox

Input 1500rpm Output 500rpm Worm RV Gearboxes Speed Reducer Reductor de vdlocidad Washing Machine

Transpeed TF-83SC Automatic Gearbox Transmission Steel Kit for Luxgen

Foton Howo Shacman Eaton 15ton GVM Heavy Duty Truck 4×4/6X6 3600Nm Transfer Gearbox with High&Low Speed Ratio Parking Drum

Factory Direct s Printer Special Repair Parts Aluminum Alloy Die Cast Gearbox