PRODUCT PARAMETERS

Description

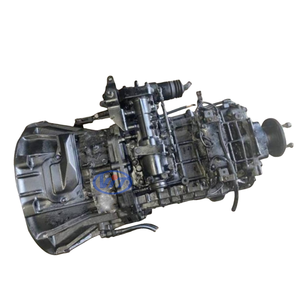

Introduction of Transmission gearbox high speed driven gear teeth 36 for tricycle transmission

Transmission gearbox high speed driven gear teeth 36 for tricycle transmission, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.Transmission gearbox high speed driven gear teeth 36 for tricycle transmission is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of Transmission gearbox high speed driven gear teeth 36 for tricycle transmission

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(Transmission gearbox high speed driven gear teeth 36 for tricycle transmission)

Specification of Transmission gearbox high speed driven gear teeth 36 for tricycle transmission

This high-speed driven gear fits tricycle transmissions. It has 36 precisely reduced teeth. The tooth count is critical. It determines just how fast the result shaft spins relative to the input. Thirty-six teeth deliver the right rate proportion for several common tricycle configurations.

We make this equipment from challenging alloy steel. The steel obtains unique warm treatment. This procedure solidifies the surface. A difficult surface area stands up to wear much better. It also stops the teeth from deforming under hefty loads. The equipment core stays somewhat softer. This keeps the component strong generally. It prevents fracturing.

Every tooth gets machined precisely. Accuracy cutting makes certain smooth interaction with the mating equipment. Smooth meshing lowers noise. It reduces resonance. Less vibration implies much less stress on bearings. Your transmission runs quieter. It lasts longer.

The gear teeth include an enhanced profile. This profile reduces friction during power transfer. Less rubbing indicates much less power loss. Much more engine power gets to the back wheels. Fuel efficiency boosts. The equipment deals with high rotational rates dependably. It won’t chip or wear prematurely.

This 36-tooth gear is a straight substitute component. It fits basic tricycle transmission housings. Check your version number for compatibility. Installment is uncomplicated. Utilize the proper devices. Correct fitting together with the drive equipment is crucial. Right reaction setting protects against damages. Adhere to the maker’s torque specifications when tightening up. This equipment gives trustworthy power transfer. It keeps your trike moving efficiently under requiring conditions.

(Transmission gearbox high speed driven gear teeth 36 for tricycle transmission)

Applications of Transmission gearbox high speed driven gear teeth 36 for tricycle transmission

This high-speed driven gear with 36 teeth is a crucial component inside several tricycle gearboxes. Its job is crucial. It takes the rapid rotation from the engine and transfers that power efficiently to the back axle. This details gear design works well for tricycles needing dependable rate and drawing strength.

You find this equipment in several common tricycle setups. Guest tricycles utilize it. It assists them maintain consistent cruising rates conveniently. Cargo tricycles profit substantially also. The equipment deals with hefty tons efficiently. It gives the needed torque for relocating products. Distribution trikes rely upon its consistent power transfer for everyday courses. Industrial tricycles in factories depend upon its toughness for continuous procedure.

The 36-tooth matter offers an excellent balance. It enables the engine to run effectively at greater speeds. This converts straight to far better fuel economy. It additionally minimizes strain on the engine. The gear meshes exactly with its companion equipment. This precise interaction decreases noise and resonance. Motorcyclists experience a smoother, quieter experience.

Sturdiness is essential. These gears are built challenging. They withstand consistent high-speed use. Quality products withstand wear in time. This suggests fewer failures. It indicates lower maintenance prices for owners. The equipment handles the demands of stop-and-go city website traffic. It likewise deals with longer trips on open roads.

Performance is a major benefit. The gear makes sure responsive acceleration when needed. It helps the tricycle climb inclines simpler. Power shipment feels predictable and controlled. Vehicle drivers gain self-confidence from this dependable efficiency. The gearbox operates successfully with this component. It assists optimize the engine’s outcome.

Picking the ideal driven gear matters. This 36-tooth high-speed gear is confirmed. It offers a practical option for numerous tricycle transmission requirements. Its style focuses on lasting stamina and effective power transfer.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Transmission gearbox high speed driven gear teeth 36 for tricycle transmission

Here are 5 FAQs about the Transmission Gearbox High Speed Driven Gear (36 Teeth) for Tricycles:

What causes this 36-tooth driven gear to wear out fast? Constant high-speed use creates friction and heat. This stress wears down the gear teeth over time. Poor lubrication makes this worse. Dirt getting into the gearbox also speeds up wear. Regular oil changes help the gear last longer.

What material is this high-speed driven gear made from? We use hardened steel. This material is strong. It handles the high forces and speeds inside the tricycle transmission. Hardened steel resists wear better than softer metals. This gives the gear a longer working life.

Will this 36-tooth gear fit my specific tricycle model? Check the part number against your original gear. Gearbox designs vary between tricycle brands and models. The tooth count must match the driving gear exactly. Using the wrong gear causes poor performance and damage. Verify compatibility before buying.

How difficult is it to install this driven gear? Installation needs mechanical skill. You must open the transmission case. This requires special tools and knowledge. Proper gear alignment is critical. Incorrect installation leads to noise and failure. We recommend professional help if you lack experience.

How often should I check this high-speed gear? Inspect it during regular transmission service. Follow your tricycle’s maintenance schedule. Look for chipped, cracked, or worn teeth. Listen for unusual grinding noises while riding. Replace the gear immediately if you find damage. Waiting causes bigger transmission problems.

(Transmission gearbox high speed driven gear teeth 36 for tricycle transmission)

REQUEST A QUOTE

RELATED PRODUCTS

DC 3-6V 200RPM TT Motor Metal Gear Motor Gearbox With 15cm 2P KF2510 Connector Cable for mbot Smart Robot Car

factory wholes the other auto transmission TOYOTta RAV4 CAMRY TRANSMISSION AUTOMATIC GEARBOX LOW MILES

Manual Gearbox D-MAX 4JB1 4WD 4X4 Gearbox And Clutch Housing For Isuzu Pickup NKR

Multipurpose grease Planetary gearbox reduction motor Power tool High temperature Resistant wear Resistant pressure

Three Day Shipping Helical Gearbox Ratio 7.5:1/10:1/20:1/25:1/30:1/40:1/50:1/60:1/80:1/100:1 Gearbox Motor With RV Gear Reducer