PRODUCT PARAMETERS

Description

Introduction of Factory Direct s Whole Ring Gear Gearbox

Factory Direct s Whole Ring Gear Gearbox, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.Factory Direct s Whole Ring Gear Gearbox is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of Factory Direct s Whole Ring Gear Gearbox

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(Factory Direct s Whole Ring Gear Gearbox)

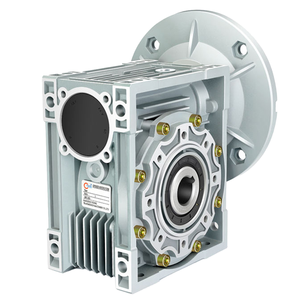

Specification of Factory Direct s Whole Ring Gear Gearbox

Factory straight entire ring gear gearboxes supply power transfer dependably. We build these systems ourselves. This means no intermediaries. You obtain the transmission straight from the resource. This configuration saves you substantial expense. It likewise quickens shipment times.

The core is the strong ring equipment. This equipment is one total piece. It is not assembled from sections. This layout is stronger. It takes care of heavy loads far better. The equipment teeth mesh efficiently. This reduces noise throughout procedure. Vibration remains reduced. Efficiency feels consistent.

Key specs matter for your application. We offer numerous sizes. Torque capability varies widely. Pick based on your tons requires. Input and result rates are flexible. We match your motor and driven equipment. Equipment proportions are precise. They guarantee the appropriate result speed. Performance scores are high. Less energy obtains lost as warm. This saves you operating prices.

These transmissions are tough. They use state-of-the-art steel. Bearings are heavy-duty. Seals maintain lube in. They additionally maintain pollutants out. Lubrication systems work. This stops very early wear. The total build extends service life. Maintenance needs stay marginal. Downtime minimizes.

Modification is feasible. We adjust installing setups. Input and outcome shaft choices exist. Flange kinds can vary. Define your exact demands. We intend to satisfy them. Our manufacturing facility control makes this less complicated. We change production swiftly.

Applications cover lots of sectors. They function well in conveyors. Mixers utilize them reliably. Hefty lifting devices relies on them. Handling equipment typically needs this kind. Anywhere strong, smooth rotation is required.

(Factory Direct s Whole Ring Gear Gearbox)

Applications of Factory Direct s Whole Ring Gear Gearbox

Factory straight entire ring gear gearboxes supply power efficiently popular situations. They manage high torque accurately. This makes them crucial throughout several durable sectors.

Mining operations rely on them. They power crushers that damage down big rocks. They drive conveyor belts relocating tons of ore. Their rugged construction holds up against constant vibration and dirt.

Building websites use these gearboxes thoroughly. They are discovered in concrete mixers making sure regular sets. They power winches lifting heavy structural beams. Excavators rely on them for smooth excavating and training activities.

Product handling systems incorporate these transmissions. They run large crane systems relocating delivery containers. They drive pallet stackers in busy stockrooms. Conveyor systems carrying items rely on their steady power outcome.

Industrial equipment usually includes these gearboxes. Hefty presses forming steel components need their strength. Large commercial mixers blending thick products utilize them. Moving mills processing steel sheets rely on their torque.

Agricultural devices advantages significantly. Combine harvesters utilize them to separate grain effectively. Large watering pumps need their reliable power transmission. Tractor carries out like tillers need their durability.

Marine applications utilize their toughness. Ship deck winches dealing with anchors and freight require trustworthy transmissions. Crane systems packing vessels rely on their high torque ability.

Reusing plants put them to work. Shredders breaking down scrap steel require extreme longevity. Sorting conveyors handling diverse materials rely upon their constant operation.

Product packaging equipment calls for precision. These gearboxes provide the controlled movement for filling, covering, and labeling lines. They make certain regular speed for high-volume production.

Power generation centers utilize them. They help drive supporting systems like huge air conditioning fans. Coal handling conveyors feeding central heating boilers require their toughness.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Factory Direct s Whole Ring Gear Gearbox

Factory Direct Whole Ring Gear Gearbox: Top 5 FAQs

What makes a whole ring gear gearbox different?

It uses one solid ring gear inside. Other gearboxes might use split gears or different designs. The solid ring gear handles heavy loads better. It spreads force more evenly. This makes the gearbox stronger overall. It lasts longer under tough conditions.

Why choose a whole ring gear design for heavy use?

The solid ring gear is key. It doesn’t have weak points like bolted joints or seams. Power transfers smoothly through the whole gear tooth. This reduces stress on individual parts. Less stress means less chance of breaking. The gearbox handles big shocks and constant heavy work reliably.

How durable is this gearbox type?

It’s built very tough. The single-piece ring gear is its main strength. There are no joints that can fail. High-quality materials and precise manufacturing make it last. It withstands extreme forces well. Expect a long service life even with demanding operations. Maintenance needs are often lower too.

Are these gearboxes energy efficient?

Yes, they usually are. The solid ring gear meshes very precisely with its pinion gear. This precise fit reduces friction losses inside. Less friction means less wasted energy. More power gets to your machinery. You save energy over time.

What industries use these gearboxes most?

They fit where strength and reliability matter most. Mining equipment relies on them for crushing and moving heavy rock. Construction machinery like cranes and excavators uses them. Large material handling systems in ports or factories need them. Steel mills and heavy processing plants depend on their toughness. Any place needing massive power transmission uses this type.

(Factory Direct s Whole Ring Gear Gearbox)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Manufacture RV Series High Torque Worm gearbox Right Angle Gearbox With Low Output Speed Reducer

Speed increasing gearbox with gear box parts and servo motor

TILI Planetary Reducer Equipped Servo Motor Original 400W Precision Gearbox 60mm Square Output Flange Gearbox

TQG CSD Series Nema 17 Precision Harmonic Reducer Zero Backlash Harmonic Gearbox Hollow Shaft Speed Reducer

Conjoined Angular Gearbox for Agricultural Machinery with Factory s