PRODUCT PARAMETERS

Description

Introduction of PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600

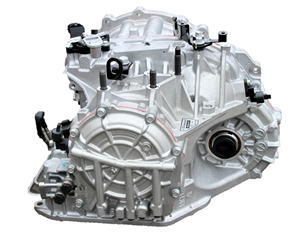

PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600 is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600)

Specification of PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600

The PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600 is a high-performance valve designed for efficient flow control in various industrial applications. This valve is constructed with ductile iron, ensuring durability and resistance to corrosion, making it suitable for use in demanding environments. The valve is designed to handle a maximum pressure rating of PN16 (16 bar), making it ideal for medium-pressure systems.

The DN600 size indicates a nominal diameter of 600mm, allowing for the management of large flow rates, which is particularly useful in water treatment plants, HVAC systems, and other large-scale industrial processes. The wafer-type design ensures a compact and lightweight structure, making installation and maintenance easier compared to traditional flanged valves. This design also allows for easy integration between flanges without the need for additional gaskets, reducing installation time and costs.

The valve features a gearbox operation mechanism, which provides precise control over the valve’s opening and closing. This gearbox mechanism enhances the valve’s performance by allowing smooth and accurate adjustments, even under high-pressure conditions. The butterfly disc, typically made of high-quality materials such as stainless steel or epoxy-coated ductile iron, ensures a tight seal and minimal leakage when the valve is in the closed position.

The PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600 is designed to operate efficiently with a wide range of media, including water, air, and other non-corrosive fluids. Its robust construction and reliable performance make it a cost-effective solution for industries requiring dependable flow control. Additionally, the valve is compliant with international standards, ensuring quality and safety in its operation. Whether used in municipal water systems, industrial pipelines, or other applications, this valve offers a reliable and efficient solution for managing fluid flow.

(PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600)

Applications of PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600

The PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600 is a highly versatile and reliable valve designed for a wide range of industrial applications. Its robust construction and advanced features make it an ideal choice for controlling the flow of liquids, gases, and slurries in demanding environments. The valve is engineered with a ductile iron body, which provides exceptional strength and durability, ensuring long-term performance even under high-pressure conditions.

One of the primary applications of this valve is in water treatment and distribution systems. Its ability to handle large flow rates and withstand varying pressure levels makes it suitable for use in pipelines, reservoirs, and pumping stations. The wafer-type design allows for easy installation between flanges, reducing downtime and maintenance costs. Additionally, the gearbox operation ensures smooth and precise control of the valve, enabling efficient flow regulation in critical processes.

In the oil and gas industry, the PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600 is widely used for pipeline isolation and flow control. Its tight sealing mechanism and resistance to corrosion make it an excellent choice for handling hydrocarbons, crude oil, and natural gas. The valve’s compact design and lightweight construction also contribute to its suitability for offshore and onshore installations, where space and weight considerations are crucial.

The valve is also commonly employed in HVAC systems, where it regulates the flow of air and water in heating, ventilation, and air conditioning networks. Its ability to operate efficiently in both high and low-temperature environments ensures reliable performance in diverse climatic conditions. Furthermore, the gearbox actuator allows for manual or automated operation, providing flexibility in system integration.

Overall, the PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600 is a dependable solution for industries requiring precise flow control, durability, and ease of installation. Its adaptability to various applications, combined with its robust construction, makes it a valuable component in modern industrial systems.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600

The PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600 is a robust and reliable valve designed for controlling the flow of liquids and gases in various industrial applications. Here are five frequently asked questions about this product:

1. **What is the pressure rating of the PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600?**

The PN16 designation indicates that this valve has a pressure rating of 16 bar (approximately 232 psi). This makes it suitable for medium-pressure applications in water supply, wastewater treatment, and other industrial systems.

2. **What materials are used in the construction of this valve?**

The valve body is made of ductile iron, which provides excellent strength and durability. The disc is typically made of stainless steel or ductile iron with an epoxy coating to resist corrosion. The seat is often made of EPDM, NBR, or other elastomers, ensuring a tight seal and long service life.

3. **What is the operating temperature range for this valve?**

The operating temperature range depends on the seat material. For EPDM seats, the valve can handle temperatures from -15°C to 120°C (5°F to 248°F). For NBR seats, the range is -10°C to 80°C (14°F to 176°F). Always check the seat material specifications for your specific application.

4. **How does the gearbox operation work?**

The gearbox mechanism allows for smooth and precise control of the valve, even in high-pressure or large-diameter applications. It reduces the effort required to operate the valve manually and ensures accurate positioning of the disc for optimal flow control.

5. **Is this valve suitable for both horizontal and vertical installation?**

Yes, the PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600 can be installed in both horizontal and vertical orientations. However, ensure proper support and alignment during installation to avoid stress on the valve and pipeline.

This valve is an excellent choice for applications requiring reliable flow control, durability, and ease of operation. Its robust construction and versatile design make it a popular option in various industries.

(PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600)

REQUEST A QUOTE

RELATED PRODUCTS

Gear s Plastic gears Spur gears for gearbox drives

Factory Direct High-Tech Custom Turbo 400 Billet Steel Gear New Stainless Steel Spur Gear Core Components Engine Pump Gearbox

Modern Novel Design Factory Ring Gear Gearbox

Holder Block CNC Lathing Distance Place Lab-on-Chip Diagnostic PCR Tests 220V Motor Engine Gear Gearbox Bearing PLC CNC Pump

Mechanical Transmission Gearbox