PRODUCT PARAMETERS

Description

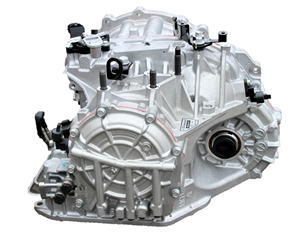

Introduction of Gear s Plastic gears Spur gears for gearbox drives

Gear s Plastic gears Spur gears for gearbox drives, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.Gear s Plastic gears Spur gears for gearbox drives is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of Gear s Plastic gears Spur gears for gearbox drives

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(Gear s Plastic gears Spur gears for gearbox drives)

Specification of Gear s Plastic gears Spur gears for gearbox drives

Gear spurs, also known as spur gears or gear teeth, are important components in gearboxes that transmit power from the engine to the wheels. They help to reduce friction and increase efficiency by reducing the number of teeth on each gear.

One of the key specifications of gear spurs is their size and shape. The size of the spur determines its width and pitch, which affect how well it fits into the housing of the gearbox. The shape of the spur determines how it meets the requirements of the gear being driven. For example, some spur designs may be designed to fit better into certain types of gears, while others may be more efficient at transmitting power to specific speeds.

Another important specification of gear spurs is their material. Different materials can provide different levels of strength and durability. Some gears may require higher-strength spur designs to withstand the forces they generate, while others may be able to tolerate lower-strength spur designs without suffering significant damage.

In addition to these basic specifications, there are several other factors that can affect the performance of gear spurs. For example, the design of the spur may also influence its ability to rotate smoothly and quietly. This is especially important for,。

Overall, specification of gear spurs plays an important role in ensuring that the gears in a gearbox work efficiently and reliably. By carefully selecting and testing the specifications of gears and spur designs, engineers and manufacturers can create gearboxes that meet the needs of their customers.

(Gear s Plastic gears Spur gears for gearbox drives)

Applications of Gear s Plastic gears Spur gears for gearbox drives

Gear spurs are widely used in the world of industrial and automotive applications to provide efficient, reliable and long-lasting drive systems. Gear spurs are installed at the end of gears to transmit power from one tooth to another. They help in reducing friction, wear, and noise in the system.

In gearboxes, spurs play a crucial role in transferring power to the teeth that rotate. They reduce the rotation speed and increase the rotational velocity of each tooth, thereby increasing the overall efficiency of the transmission. Gear spurs also help in maintaining correct alignment between the gears, ensuring that they turn smoothly and efficiently.

In addition to their use in drives, spurs are also used in other applications such as pumps, fans, and motors. For example, in pumps, spurs are used to convert mechanical energy into electrical energy. Similarly, in fans, spurs are used to generate mechanical power and rotate them, enabling the fan to move air.

Overall, Gear spurs are an essential component of modern industrial and automotive drive systems. Their use helps in achieving high efficiency, reliability, and durability, making them a popular choice among engineers and technicians worldwide.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Gear s Plastic gears Spur gears for gearbox drives

1. What is Gear S Plastic gears Spur gears for Gear Drives?

Gear S Plastic gears and spur gears are both types of gears used in gearboxes to reduce power output and increase efficiency.

2. How does Gear S Plastic gears work?

Gear S Plastic gears are made from durable materials that provide excellent strength, wear resistance, and shock absorption. The teeth on the gears are made of plastic, which allows them to be lightweight while still maintaining high levels of performance.

3. Are Gear S Plastic gears compatible with different brands of gearboxes?

Yes, Gear S Plastic gears are compatible with a wide range of gears and transmission systems, including those found in cars, trucks, and other industrial applications.

4. Why are Gear S Plastic gears better than metal gears?

S。,、。

5. How do I choose the right type of Gear S Plastic gears or spur gears for my application?

When choosing Gear S Plastic gears or spur gears for your application, it’s important to consider factors such as the intended usage, the size of the engine, and the specific requirements of your application. You should also consult with a professional if you’re unsure about which type of gear would be best for your situation.

(Gear s Plastic gears Spur gears for gearbox drives)

REQUEST A QUOTE

RELATED PRODUCTS

QY3D high torque ZQ bevel transmission gearbox for concrete mixer

3F FAMED High Precision & Rigifity &Torque 1 Stage VRB090 Servo Motor Planetary Gearbox Planetary Servo Gearbox

R Series Agricultural HELICAL gearbox Ratio Reduction gearbox Drive R Series gearbox With Brushless 220 V 0.50 Kw Gear Motor

02E DSG TCU Transmission Control Unit 02E927770AJ 02E927770AD DQ250 Gearbox Mechatronic Transmission Control Module Valve Body

Durable And High Quality Iron Cast Gear Reduction Worm Gearbox High Precision Wp Worm Gearbox