PRODUCT PARAMETERS

Description

Introduction of gearbox transmission gear drive

gearbox transmission gear drive, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.gearbox transmission gear drive is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of gearbox transmission gear drive

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

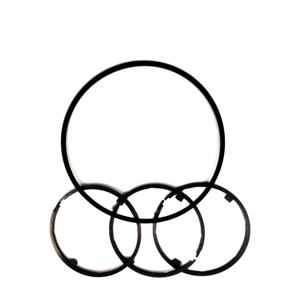

(gearbox transmission gear drive)

Specification of gearbox transmission gear drive

This gearbox transmission gear drive moves power from engines to where it’s needed. It changes speed and torque using different sized gears meshing together. This lets engines work better across various speeds and loads.

The gear ratios are critical. They determine how much the input speed changes to output speed. Common setups include single or multiple gear stages. Each stage offers specific ratio options. Gear tooth profiles matter too. Precise helical or spur gear shapes ensure smooth engagement. They reduce noise and wear during operation.

Materials used must handle heavy forces. Steel alloys are standard for gears and shafts. Heat treatments like carburizing make surfaces extremely hard. This prevents pitting and extends service life. Bearings support rotating parts. They minimize friction inside the housing.

Lubrication is essential. Oil or grease keeps gears cool. It prevents metal-to-metal contact. Seals keep lubricant in. They also keep dirt and water out. This protects internal components.

Efficiency measures power loss. Well-made gear drives lose very little power. Most power input reaches the output shaft. Low friction designs and quality lubrication help achieve this. Lower losses save energy and reduce heat.

Load capacity defines the maximum force it can handle. This depends on gear size, material strength, and bearing ratings. Designers calculate this based on application demands. Safety factors are always included.

Mounting options are flexible. Flanges, feet, or hollow shafts provide different connection points. This allows installation in various machines. Common applications include industrial equipment, vehicles, and heavy machinery. It reliably transfers power where rotation speed needs adjustment.

(gearbox transmission gear drive)

Applications of gearbox transmission gear drive

Gearbox transmission gear drives do important work in many machines. They move power from engines or motors to the places needing it. Gearboxes change how fast things turn and how strong the turning force is. This makes them very useful.

Cars and trucks use gearboxes every day. The engine spins fast. The gearbox adjusts this speed and force to turn the wheels properly. Different gears help the vehicle start moving, climb hills, or drive fast on the highway smoothly.

Factories rely heavily on gear drives. Conveyor belts moving boxes, mixers stirring ingredients, big presses shaping metal – all use gearboxes. The gearbox takes the steady power from a big electric motor and makes it right for each job. It controls the speed and torque needed.

Wind turbines need gearboxes too. The huge blades turn slowly in the wind. The gearbox increases this slow speed so the generator inside can produce electricity efficiently. This change is critical for making power.

Heavy equipment like bulldozers and cranes uses strong gear drives. These machines lift heavy loads and push dirt. Gearboxes provide the massive turning force required. They handle tough conditions reliably.

Robots in factories often have small, precise gearboxes in their joints. These let the robot arm move accurately and hold positions steady. The gearbox makes the motor’s motion smooth and controlled for delicate tasks.

Food processing plants, printing presses, and mining equipment also depend on gear drives. They are everywhere power needs moving, speed needs changing, or force needs increasing. Gearboxes make modern machines work right. They are fundamental parts turning power into useful motion across countless applications.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of gearbox transmission gear drive

People often ask about gearbox transmission gear drives. Here are five common questions answered simply.

What does a gearbox transmission gear drive actually do?

It moves power. An engine or motor spins fast. The gearbox uses gears to change this speed and torque. Then it sends this adjusted power to the wheels or other machine parts. This lets the machine work right.

Is a gear drive different from other transmissions?

Yes. Gear drives use metal gears meshing together. Other types, like belts or chains, use flexible parts. Gear drives are strong. They handle heavy loads well. They are precise. They are common in tough machines needing reliable power transfer.

Why do gear drives sometimes fail?

Several things cause problems. Not enough oil is a big reason. Gears need lubrication. Dirt getting inside the gearbox damages gears. Misalignment puts stress on parts. Overloading the gearbox forces it beyond its limits. Poor maintenance lets small issues become big failures.

How important is the oil inside the gearbox?

Extremely important. The oil lubricates the gears. This reduces friction. Less friction means less heat and wear. It also helps cool the gears. Clean oil is crucial. Dirty oil carries damaging particles. Using the wrong oil type can harm the gears too. Check oil levels regularly. Change the oil as recommended.

What signs show a gear drive might have trouble?

Listen and look. Strange noises like grinding or whining often mean trouble. Leaking oil is a bad sign. Finding metal bits in the oil is serious. Excessive vibration while running points to imbalance or damage. Difficulty shifting gears indicates internal problems. Notice any of these? Get the gearbox checked fast.

(gearbox transmission gear drive)

REQUEST A QUOTE

RELATED PRODUCTS

VT1 VT2 VT3 CVT Original New Automatic Transmission Gearbox For BMW Mini COOPER Lifan X60

Hydraulic Planetary Gear Rotary Reducer High Torque Planetary Hydraulic Transmission Drive Gearbox with motor for drilling rig

KL016004 New Gearbox Core Component for Container Lifting Transport System in Manufacturing Plants Material Handling Equipment

Extruder gearbox for plastic extruder ZLYJ extruder gearbox

100% New 513MHA Auto Manual Transmission Gearbox For Chery Yoya