PRODUCT PARAMETERS

Description

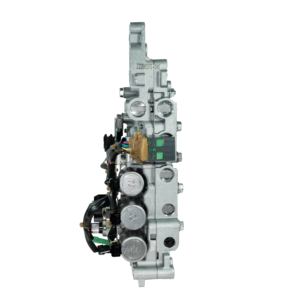

Introduction of Advance / Fada Transmission Gearbox 120C 135A 300 HC400

Advance / Fada Transmission Gearbox 120C 135A 300 HC400, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.Advance / Fada Transmission Gearbox 120C 135A 300 HC400 is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of Advance / Fada Transmission Gearbox 120C 135A 300 HC400

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(Advance / Fada Transmission Gearbox 120C 135A 300 HC400)

Specification of Advance / Fada Transmission Gearbox 120C 135A 300 HC400

The Advance/Fada Transmission Gearbox series includes the 120C, 135A, 300, and HC400 models. These gearboxes handle high torque demands. They are built for tough industrial settings. The 120C model supports a specific torque input. The 135A offers a higher capacity. The 300 model provides even more power transfer. The HC400 is the strongest in this group. Each gearbox manages power transmission effectively. They convert motor speed into usable output. Different industries rely on these units.

These gearboxes work at various input speeds. They maintain stable performance. The output speed is adjustable. This allows precise control. Gear ratios are carefully engineered. This ensures efficient power delivery. The internal gears are hardened steel. They resist wear. Bearings are heavy-duty. They support significant loads. The housing is cast iron. It protects internal parts. Seals prevent leaks. They keep lubricant inside. They keep contaminants out.

Lubrication is vital for long life. These gearboxes use oil baths. Some models need forced lubrication systems. Cooling might be necessary. Heat builds up under heavy use. Cooling fins help. Sometimes external fans are used. Mounting is flexible. The units can be foot-mounted. They can also be flange-mounted. Shaft configurations vary. Input and output shafts can be horizontal. They can also be vertical. Shaft sizes are standardized. This fits common coupling types.

The gearboxes connect directly to motors. They connect to driven machines. Proper alignment is critical. Misalignment causes damage. Regular maintenance is essential. Operators must check oil levels. They must inspect for leaks. They must listen for unusual noises. These actions prevent unexpected failures. These Advance/Fada gearboxes are dependable. They offer consistent performance. They meet demanding application needs.

(Advance / Fada Transmission Gearbox 120C 135A 300 HC400)

Applications of Advance / Fada Transmission Gearbox 120C 135A 300 HC400

These gearboxes handle tough jobs. They move power efficiently in heavy machines. You see them in big construction equipment. Bulldozers and excavators use them. These machines need reliable power transfer. The gearboxes deliver that. Mining operations rely on them too. Big dump trucks and loaders work hard underground. These gearboxes provide the necessary torque. They stand up to constant use. Agriculture uses these gearboxes widely. Big tractors and combine harvesters need them. They power implements and drive systems. The gearboxes handle different field conditions. Material handling depends on them. Conveyor belts in factories use these gearboxes. Forklifts and cranes need smooth power control. They offer precise speed adjustments. Marine applications find them useful too. Winches and deck machinery on boats use them. They withstand saltwater environments. Industrial settings use these gearboxes daily. Pumps, compressors, and generators need dependable drives. These units provide long service life. They are built tough for demanding tasks. Durability is a key feature. Maintenance needs are low. Operators appreciate this reliability. Downtime costs money. These gearboxes help avoid that. Performance stays consistent over time. They are a solid choice for power transmission.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Advance / Fada Transmission Gearbox 120C 135A 300 HC400

What transmission models work with the Advance/Fada Gearbox 120C, 135A, 300, HC400?

These gearboxes fit specific models. Check the manual for your transmission. It lists exact matches. Use the right gearbox for your model. Wrong fits cause problems. Damage happens otherwise.

What lubricant is best for the Advance/Fada Gearbox 120C, 135A, 300, HC400?

Use the recommended gear oil. The manual specifies the type and grade. Stick to the suggested viscosity. Change the oil as scheduled. Clean oil keeps gears running smooth. Dirty oil wears parts faster.

Is installing the Advance/Fada Gearbox 120C, 135A, 300, HC400 hard?

Installation needs care. Follow the manual steps exactly. Align parts properly. Tighten bolts to the correct torque. Mistakes lead to leaks or noise. Get a professional if unsure. Proper install prevents future trouble.

How often should I service the Advance/Fada Gearbox 120C, 135A, 300, HC400?

Service it regularly. Check the maintenance schedule. Oil changes are key. Look for leaks or strange noises. Address issues quickly. Regular checks extend the gearbox life. Neglect causes breakdowns.

Are the Advance/Fada Gearbox 120C, 135A, 300, HC400 durable?

These gearboxes are built tough. They handle heavy loads. Use them correctly. Follow maintenance rules. They last a long time this way. Abuse shortens their life. Proper care ensures reliability.

(Advance / Fada Transmission Gearbox 120C 135A 300 HC400)

REQUEST A QUOTE

RELATED PRODUCTS

K Series Bevel Helical gearbox Bevel Gear Box Reducer Reductor Stm 100 ( 90 – B5 ) Bevel gearbox Rack Pinion Lift Motor

FAST transmission Gearbox high-quality Gearbox low-d second-hand Gearbox

TRANSPEED auto transmission Gearbox Assy gearbox 722.9

DG937M121DF DG9Z6068Q DG937M121DG DG9Z6068N DG9Z6068L Engine Gearbox Mounting Transmission Engine Mounting for MKZ 13 2.0

New JL473Q Gearbox MR513C01 Manual Transmission Gearbox for Changan MD201 Changan Era Star 2 Pickup