PRODUCT PARAMETERS

Description

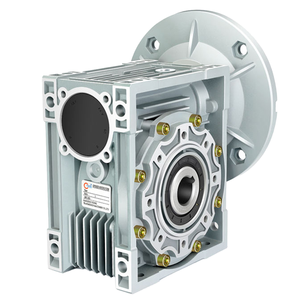

Introduction of Extruder gearbox for plastic extruder ZLYJ extruder gearbox

Extruder gearbox for plastic extruder ZLYJ extruder gearbox, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.Extruder gearbox for plastic extruder ZLYJ extruder gearbox is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of Extruder gearbox for plastic extruder ZLYJ extruder gearbox

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(Extruder gearbox for plastic extruder ZLYJ extruder gearbox)

Specification of Extruder gearbox for plastic extruder ZLYJ extruder gearbox

This extruder gearbox drives plastic extruders. It connects directly to the screw. Its job is turning the screw. This rotation pushes plastic material through the barrel. The gearbox handles the power needed for extrusion.

The ZLYJ extruder gearbox is built tough. It uses hardened alloy steel gears. These gears have high strength. They resist wear very well. The gear teeth are cut precisely. This ensures smooth power transfer. It also reduces vibration. Less vibration means smoother extrusion.

The gearbox housing is rigid. It holds the gears securely. This prevents misalignment. Proper alignment is critical. It prevents premature wear. It also protects the bearings inside. The housing is sealed tightly. This keeps lubricant in. It keeps dirt out. Good sealing extends the gearbox life.

This gearbox runs at low speeds. It produces high torque. Torque is the turning force. Plastic extrusion needs high torque. This gearbox delivers it reliably. It can handle heavy loads. It operates under constant pressure. This makes it dependable for extrusion lines.

Different models offer various ratios. The ratio determines the output speed. It matches the screw speed requirement. Users select the ratio needed for their process. The gearbox mounts easily onto extruder barrels. It fits standard extruder designs well.

The internal bearings support the shafts. They are heavy-duty bearings. They handle radial and axial forces. Lubrication is vital. The gearbox uses oil bath lubrication. The gears splash oil as they turn. This lubricates all moving parts effectively.

This gearbox is designed for durability. It minimizes energy loss. High efficiency saves power. Proper maintenance keeps it running. It needs regular oil checks. Oil changes are necessary periodically. Following maintenance schedules is important. It helps prevent unexpected failures.

The ZLYJ gearbox works in demanding conditions. It powers extruders making pipe, profiles, and sheet. It also drives machines making pellets or compound. It provides the necessary force. It ensures consistent screw rotation. This leads to stable extrusion output.

(Extruder gearbox for plastic extruder ZLYJ extruder gearbox)

Applications of Extruder gearbox for plastic extruder ZLYJ extruder gearbox

ZLYJ extruder gearboxes are important parts in plastic extrusion machines. These gearboxes handle the motor’s power and movement. They adjust the speed and force correctly. This makes the extruder screw turn at the right pace. Consistent screw rotation is key. It pushes plastic material through the barrel smoothly. The gearbox ensures this happens reliably.

The extruder screw needs steady power to work well. The ZLYJ gearbox delivers this power. It manages high torque loads. This torque is necessary for melting plastic pellets. It also pushes the molten plastic through the die. The gearbox’s tough build handles these demands. It keeps the extrusion process stable. This leads to a uniform product output.

Different plastic extrusion jobs use the ZLYJ gearbox. Making pipes and profiles requires constant pressure. The gearbox provides this. It helps create smooth surfaces and even wall thickness. Film and sheet extrusion also uses it. Here, steady screw speed is vital. It controls the melt flow rate. This affects the final film’s quality. The gearbox helps maintain this speed.

Blown film lines need precise control. The ZLYJ gearbox supports this. It allows operators to fine-tune the screw speed. This adjustment impacts the film’s properties. Even pelletizing machines rely on these gearboxes. They need dependable screw rotation for cutting plastic into pellets. The gearbox ensures the pellets are uniform. This consistency matters for quality control. The gearbox is built to last. It handles the tough conditions of plastic processing. Its reliable performance keeps production lines running.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Extruder gearbox for plastic extruder ZLYJ extruder gearbox

What makes the ZLYJ extruder gearbox reliable?

It uses strong materials. The gears and bearings are high quality. They handle tough conditions well. The design spreads the load evenly. This reduces stress points. The gearbox lasts longer. It runs smoothly under pressure.

How often does the ZLYJ gearbox need maintenance?

You need to check the oil often. Check it every month. Change the oil every six months. Look for leaks or strange noises too. Fix small problems fast. This prevents bigger failures. Good care keeps it working well.

Does the ZLYJ gearbox affect how the extruder works?

Yes it matters a lot. This gearbox controls speed and force. It must be very precise. Good speed control means even plastic output. The gearbox handles high torque. It keeps the screw turning steadily. This gives good product quality.

Is installing the ZLYJ gearbox difficult?

It needs care but is straightforward. You must align it perfectly with the motor. Wrong alignment causes damage. Follow the installation guide step by step. Tighten all bolts correctly. Check everything before starting. Proper setup avoids early wear.

Can the ZLYJ gearbox handle different extruder setups?

Yes it is adaptable. The gearbox comes in many sizes. Different ratios are available. This fits various screw diameters. It also suits different drive motors. Tell us your exact needs. We can supply the right gearbox for your machine.

(Extruder gearbox for plastic extruder ZLYJ extruder gearbox)

REQUEST A QUOTE

RELATED PRODUCTS

Truck Parts For ZF6AP1700 Gearbox Assembly Gearbox

Worm Gearbox 48v 1 Kw Second Hand Speed Reducer With DC Motor Worm Gearbox For Conveyor

Customized AB Serious Helical Gears Planetary Gearbox

ZDY DBY series Cone-column Cylindrical Hardened reducer gearbox for paper shredder

Transmission Gearbox for VOLKSWAGEN POLO IV 1.4 ADVANCE 307033