PRODUCT PARAMETERS

Description

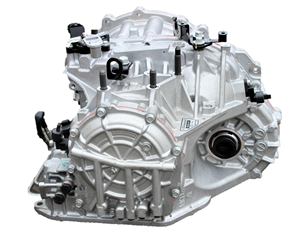

Introduction of TQG Large Diameter Hollow Shaft gearbox Hollow Rotating Platform High Precision Planetary gearbox DG Series

TQG Large Diameter Hollow Shaft gearbox Hollow Rotating Platform High Precision Planetary gearbox DG Series, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.TQG Large Diameter Hollow Shaft gearbox Hollow Rotating Platform High Precision Planetary gearbox DG Series is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of TQG Large Diameter Hollow Shaft gearbox Hollow Rotating Platform High Precision Planetary gearbox DG Series

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(TQG Large Diameter Hollow Shaft gearbox Hollow Rotating Platform High Precision Planetary gearbox DG Series)

Specification of TQG Large Diameter Hollow Shaft gearbox Hollow Rotating Platform High Precision Planetary gearbox DG Series

The TQG Large Diameter Hollow Shaft Gearbox (DG Series) is a high-precision planetary gearbox designed for heavy-duty industrial applications. It features a hollow rotating platform with a large inner diameter, enabling seamless integration of cables, pipes, or shafts through the center. This design reduces external wiring clutter, simplifies installation, and enhances system reliability. The gearbox delivers high torque output while maintaining compact dimensions, making it ideal for space-constrained setups. Precision engineering ensures minimal backlash, high positional accuracy, and smooth motion control. This suits applications like robotics, automation equipment, CNC machinery, and rotary indexing tables. The DG Series supports radial and axial loads simultaneously due to its robust bearing structure. It handles high moment loads without compromising performance. The hollow shaft diameter ranges from 50mm to 600mm, accommodating diverse mechanical requirements. Torque capacities extend up to 50,000Nm, catering to both light and heavy machinery. The gearbox uses helical planetary gears for efficient power transmission and reduced noise during operation. Heat-treated alloy steel components enhance durability and wear resistance. Sealing technology protects internal parts from dust, moisture, and debris, ensuring long service life in harsh environments. Multiple mounting options include flange, foot, and shaft configurations for flexible integration. Customization is available for gear ratios, input/output interfaces, and lubrication types. The DG Series supports direct motor coupling via compatible adapters, simplifying drive system assembly. Precision grinding of gears and bearings guarantees consistent performance under high-speed or high-load conditions. Maintenance requirements are minimal due to the sealed, lubrication-filled design. The gearbox operates efficiently across temperatures from -20°C to 80°C. Compliance with international standards ensures reliability in global industrial markets. Applications span packaging machinery, material handling systems, aerospace test rigs, and medical device manufacturing. The combination of high rigidity, precision, and adaptability makes the DG Series a versatile solution for advanced motion control challenges.

(TQG Large Diameter Hollow Shaft gearbox Hollow Rotating Platform High Precision Planetary gearbox DG Series)

Applications of TQG Large Diameter Hollow Shaft gearbox Hollow Rotating Platform High Precision Planetary gearbox DG Series

The TQG Large Diameter Hollow Shaft gearbox delivers high torque and precision for industrial automation. Its hollow shaft design allows cables, pipes, or lasers to pass through. This reduces clutter in robotic arms, CNC machines, and assembly lines. The Hollow Rotating Platform supports smooth 360-degree rotation. It is ideal for applications requiring precise angular positioning. Examples include automated welding systems, rotary tables, and semiconductor handling equipment.

The High Precision Planetary gearbox DG Series offers low backlash and high rigidity. It ensures accurate motion control in tasks like pick-and-place robots, medical imaging devices, and optical alignment systems. The compact structure saves space in machinery. It handles heavy loads without sacrificing performance. This makes it suitable for packaging lines, material handling robots, and printing presses.

Durability is a key feature. The gearbox uses hardened steel gears and advanced lubrication. These components withstand harsh conditions like dust, high temperatures, and continuous operation. Maintenance needs are minimal. Users save time and costs over the product’s lifespan.

Integration is simple. The hollow shaft design works with servo motors, stepper motors, and direct-drive systems. Engineers adapt it to existing setups easily. Custom mounting options and flange sizes are available. This flexibility meets specific requirements in automation projects.

The Hollow Rotating Platform supports high radial and axial loads. It ensures stability in applications like solar panel tracking systems, radar antennas, and camera gimbals. High precision repeatability guarantees consistent results in automated inspection systems.

The DG Series planetary gearbox excels in high-speed scenarios. Its balanced construction minimizes vibration. Noise levels stay low even under heavy loads. This is critical for environments like laboratories or medical facilities.

These gearboxes are used across industries. Robotics relies on them for joint movement and precision. Automotive assembly lines use them for part positioning. Renewable energy systems apply them for solar tracker rotation. Medical devices depend on their accuracy for imaging and surgical tools.

Customization options include different reduction ratios, shaft configurations, and sealing solutions. This ensures compatibility with diverse operational demands.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of TQG Large Diameter Hollow Shaft gearbox Hollow Rotating Platform High Precision Planetary gearbox DG Series

The TQG Large Diameter Hollow Shaft gearbox DG Series is built for precision motion control. Here are five common questions about it.

What applications is the DG Series gearbox suitable for?

The DG Series works in robotics, CNC machinery, automated assembly lines, and medical equipment. The hollow shaft design lets users route cables, hoses, or mechanical parts through the center. This reduces external clutter. It supports rotary and indexing motions.

Why is the DG Series called high-precision?

Its planetary gear structure minimizes backlash. High-grade bearings and optimized gear meshing ensure positioning accuracy under 1 arc-minute. Tight manufacturing tolerances keep performance stable over time. This is critical for tasks like laser cutting or inspection.

How large is the hollow shaft?

Hollow bore sizes range from 50mm to 600mm. Custom diameters are available. The space accommodates multiple cables or pneumatic lines. It eliminates the need for external cable carriers. This reduces maintenance and failure risks.

Can it handle heavy loads?

Yes. The DG Series uses hardened steel gears and reinforced housing. Axial and radial load capacities reach up to 15,000N and 30,000N respectively. It withstands sudden shifts in torque. Industrial shock or vibration rarely affects its operation.

Does it require frequent maintenance?

No. Grease lubrication lasts over 10,000 hours. Sealed housings block dust and moisture. Users only need annual checks for abnormal noise or wear. Replacement parts are standardized for easy servicing.

(TQG Large Diameter Hollow Shaft gearbox Hollow Rotating Platform High Precision Planetary gearbox DG Series)

REQUEST A QUOTE

RELATED PRODUCTS

Kingcat Excavator Spare Parts SY210 Swing Reduction Gearbox For Sany Excavator SY220 SY230 SY240 Swing Gearbox

RV Worm Gearbox, Self-locking Gearbox, Matching Servo / Stepper Motor Gearbox NEMA34 OEM Automation Equipment Worm Gear Box

Gearbox Precision speed reducer transmission gearbox

China factory excavator spare part speed reducer transmission reduction planetary gearbox

Transmission Gearbox/Gear Box of Agricultural Farm Tractor with PTO shaft