PRODUCT PARAMETERS

Description

Introduction of TILI F Series FAF Type Helical Gear Motor Speed Reducer AC Electric Transmission Gear Motor Gearbox Speed Reducers

TILI F Series FAF Type Helical Gear Motor Speed Reducer AC Electric Transmission Gear Motor Gearbox Speed Reducers, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.TILI F Series FAF Type Helical Gear Motor Speed Reducer AC Electric Transmission Gear Motor Gearbox Speed Reducers is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of TILI F Series FAF Type Helical Gear Motor Speed Reducer AC Electric Transmission Gear Motor Gearbox Speed Reducers

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

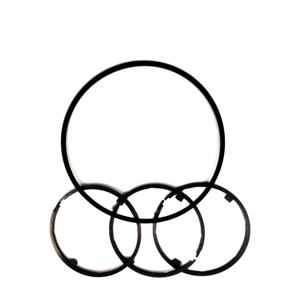

(TILI F Series FAF Type Helical Gear Motor Speed Reducer AC Electric Transmission Gear Motor Gearbox Speed Reducers)

Specification of TILI F Series FAF Type Helical Gear Motor Speed Reducer AC Electric Transmission Gear Motor Gearbox Speed Reducers

The TILI F Series FAF Kind Helical Equipment Motor Rate Reducer is a high-performance transmission solution created for commercial applications calling for accurate speed control, sturdiness, and energy efficiency. This gear motor combines an a/c electrical motor with a helical equipment reducer, offering smooth procedure, low noise, and high torque outcome. Its durable construction makes sure reputable efficiency popular settings such as mining, building and construction, material handling, and production. The helical gear design offers superior lots circulation throughout gear teeth, decreasing wear and prolonging life span compared to typical spur equipment systems. The FAF collection includes a compact, space-saving design with numerous placing options (foot-mounted, flange-mounted, or shaft-mounted) to fit varied setup demands. It sustains input power varies from 0.12 kW to 200 kW, with speed decrease proportions spanning 5:1 to 100:1, allowing modification for specific operational demands. The gearbox real estate is created from high-strength cast iron, ensuring strength and resistance to shock tons. Precision-machined helical gears made from hardened alloy steel deliver high transmission efficiency (as much as 95%) and minimal power loss. Secured bearings and progressed lubrication systems enhance resilience while lowering maintenance needs. The incorporated air conditioning motor operates at voltages of 220V/380V/415V and frequencies of 50Hz/60Hz, compatible with basic commercial power products. Secret requirements consist of an outcome torque range of up to 18,000 Nm, input speeds up to 1,500 RPM, and an operating temperature level series of -10 ° C to 40 ° C. The equipment motor is IP65-rated for dust and water resistance, making sure integrity in harsh problems. Optional thermal defense and anti-corrosion coatings further boost versatility to severe environments. Ideal for conveyors, mixers, crushers, and packaging equipment, the TILI F Series FAF Helical Gear Electric Motor Speed Reducer is accredited to fulfill ISO 9001, CE, and various other international criteria, guaranteeing high quality and safety. Customized configurations for shaft sizes, flanges, and motor kinds are readily available to fulfill specialized application demands.

(TILI F Series FAF Type Helical Gear Motor Speed Reducer AC Electric Transmission Gear Motor Gearbox Speed Reducers)

Applications of TILI F Series FAF Type Helical Gear Motor Speed Reducer AC Electric Transmission Gear Motor Gearbox Speed Reducers

The TILI F Collection FAF Type Helical Equipment Electric Motor Speed Reducer is a flexible and robust option made for air conditioner electric transmission systems, supplying effective power transfer, high torque output, and dependable efficiency throughout diverse industrial applications. Its helical gear layout ensures smooth, silent operation, making it excellent for settings where sound decrease and accuracy are crucial.

In production and automation, this gear motor masters driving conveyor systems, assembly lines, and robot equipment. Its ability to handle heavy loads with minimal vibration ensures consistent production rates and extended devices life expectancy. The small layout saves area while keeping high torque ability, necessary for limited factory designs.

The food and drink industry gain from the FAF Series’ resilience and adaptability. It powers mixers, bottling lines, and product packaging equipment, with alternatives for stainless steel building or safety coverings to meet hygiene criteria. The reducer’s reduced upkeep needs and resistance to dampness and pollutants lower downtime popular handling settings.

Mining, building, and farming sectors depend on this equipment motor for sturdy applications such as crushers, excavators, harvesters, and irrigation systems. Its durable build withstands extreme conditions, including dirt, particles, and temperature level changes, ensuring reliable operation in off-road and heavy-duty scenarios.

Material handling systems, including cranes, hoists, and stockroom automation, utilize the reducer’s smooth torque delivery for risk-free training and exact positioning. In water treatment plants, it drives pumps and aerators, with corrosion-resistant versions offered for extended exposure to harsh chemicals.

Renewable resource applications, such as wind generator pitch control and solar tracking systems, utilize the FAF Series for reliable power transmission and versatility to variable rates. Its energy-efficient layout lines up with sustainability objectives while lowering functional expenses.

Customizable installing setups, equipment proportions, and electric motor compatibility make the TILI F Collection FAF Kind a versatile option for tailored remedies. Whether in high-speed packaging, wastewater monitoring, or precision agriculture, this helical gear motor supplies unparalleled efficiency, durability, and efficiency, sealing its duty as an essential component in modern commercial procedures.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of TILI F Series FAF Type Helical Gear Motor Speed Reducer AC Electric Transmission Gear Motor Gearbox Speed Reducers

**1. What are the primary applications of the TILI F Series FAF Helical Gear Motor Speed Reducer?**

The TILI F Series FAF Helical Gear Motor is designed for heavy-duty industrial applications requiring high torque and precise speed reduction. It is commonly used in conveyors, mixers, agitators, packaging machinery, construction equipment, and material handling systems. Its robust helical gear design ensures smooth, low-vibration operation, making it ideal for environments demanding reliability, durability, and energy efficiency.

**2. How does the helical gear design improve performance compared to other gear types?**

Helical gears in the TILI F Series feature angled teeth that engage gradually, reducing noise and vibration while increasing load distribution across multiple teeth. This design enhances operational smoothness, minimizes wear, and extends service life compared to spur gears. The improved contact ratio also boosts torque capacity and efficiency, making it suitable for high-stress, continuous-duty applications.

**3. What maintenance is required for the TILI F Series gear reducer?**

The TILI F Series is built for minimal maintenance. Key steps include periodic oil checks (every 3–6 months) and lubrication replacement as specified in the manual (typically after 5,000–10,000 operating hours). Sealed bearings and high-quality housing reduce contamination risks. Regular inspection for leaks, abnormal noise, or overheating ensures optimal performance. Always use manufacturer-recommended lubricants.

**4. Can this gear motor operate in harsh environments?**

Yes. The TILI F Series features an IP65-rated enclosure (optional higher ratings available), protecting against dust, moisture, and moderate chemical exposure. Its hardened helical gears and corrosion-resistant materials ensure reliable performance in extreme temperatures (-20°C to 50°C) and high-humidity conditions. Optional coatings or seals can be added for additional protection in aggressive industrial settings.

**5. Are customization options available for specific torque or speed requirements?**

Absolutely. The TILI F Series offers flexible customization, including torque ranges from 100 Nm to 18,000 Nm and output speeds from 0.05 RPM to 300 RPM. Mounting configurations (foot-mounted, flange-mounted, or shaft-mounted), gear ratios, and motor power (0.12 kW to 200 kW) can be tailored to match application needs. Customized input voltages (e.g., 230V/415V AC) and optional brakes or encoders are also available. Contact the supplier with your specifications for a tailored solution.

(TILI F Series FAF Type Helical Gear Motor Speed Reducer AC Electric Transmission Gear Motor Gearbox Speed Reducers)

REQUEST A QUOTE

RELATED PRODUCTS

TQG VRL Series Bevel Gear Nema 34 Planetary Gearbox Servo Motor Gearbox With High Precision

Guangdong direct factory 3 years guarantee plastic gearbox fan parts motor gearbox

high precision speed reducer planetary gear reducer gearbox for nema 34 stepper motor

Industrial Bevel Gears For Various Industries Used In Gearboxes For Efficient Spur Gear Transmission

Manual Transmission gearbox parts for Toyota Hilux Hiace 2L 3L 3Y 4Y 5L 2RZ 1RZ