PRODUCT PARAMETERS

Description

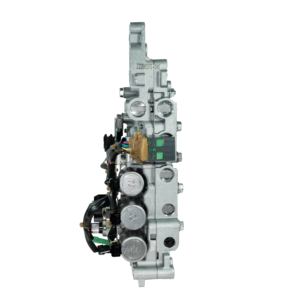

Introduction of Solid Shaft High power Transmission gearbox High Torque Industrial Gearbox

Solid Shaft High power Transmission gearbox High Torque Industrial Gearbox, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.Solid Shaft High power Transmission gearbox High Torque Industrial Gearbox is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of Solid Shaft High power Transmission gearbox High Torque Industrial Gearbox

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(Solid Shaft High power Transmission gearbox High Torque Industrial Gearbox)

Specification of Solid Shaft High power Transmission gearbox High Torque Industrial Gearbox

This industrial transmission deals with heavy lots. It utilizes strong steel shafts. These shafts are solid. They don’t bend easily. This arrangement transmits high power effectively. You get optimal torque transfer. Torque measures transforming force. This transmission provides high torque continually. It powers demanding commercial devices accurately.

The gearbox includes rugged building and construction. It utilizes strong steel alloys. These products resist damage. Internal gears are accuracy cut. This makes sure smooth meshing. Smooth meshing decreases vibration and noise. It additionally enhances life-span. Bearings support the shafts securely. Durable bearings deal with radial and axial forces. This prevents shaft deflection under tons.

Sealing secures internal parts. High-quality seals keep out dirt and wetness. This is essential in rough factory environments. Contamination triggers premature failure. Excellent seals prolong service life. Lubrication is crucial. Correct oil circulation reduces friction. Decreased rubbing avoids overheating. Overheating problems gears and bearings. Routine upkeep checks oil degrees.

This gearbox matches several difficult applications. It runs conveyor belts relocating hefty products. It powers huge mixers in processing plants. It drives crushers and shredders managing strong waste. It runs heavy-duty pumps in mining. It turns huge followers in ventilation systems. Its style handles constant operation. It handles unexpected load spikes without damages. Installment needs a solid foundation. Vibration needs to be minimized. Proper alignment with the motor is necessary. Imbalance creates tension and early failure.

(Solid Shaft High power Transmission gearbox High Torque Industrial Gearbox)

Applications of Solid Shaft High power Transmission gearbox High Torque Industrial Gearbox

Solid shaft high power transmission gearboxes provide major muscle mass. They move large machines requiring great deals of transforming force, high torque. These gearboxes are developed strong for difficult commercial work. They take care of huge loads without breaking. You discover them where power matters most.

Mining procedures rely upon them heavily. They power enormous crushers damaging rock. They drive large conveyor belts relocating lots of ore. These work require continuous, reliable power. The gearbox gives it. Mining devices faces rough problems. This gearbox withstands the punishment.

Heavy product handling uses these gearboxes as well. Think large cranes raising steel light beams. Assume large container lifts relocating grain or coal. The transmission transforms the drums lifting these hefty weights. Accuracy control is essential for security. The gearbox provides smooth, trustworthy procedure.

Steel mills and cement plants require this power. They run massive rolling mills shaping steel. They drive significant rotary kilns baking clinker. The warmth and vibration are extreme. The strong shaft gearbox manages it. It moves engine power effectively to the job point. Downtime costs money here. Integrity is non-negotiable.

Handling markets depend upon them. Large mixers blend thick products. Big agitators stir heavy slurries in storage tanks. Extruders press thick items through dies. These tasks call for tremendous transforming pressure. The transmission provides it consistently. It keeps production lines moving.

Power generation uses these durable systems. They attach generators to generators. They deal with the massive torque result. Constant speed conversion is important. The transmission guarantees steady electrical power production. Marine propulsion also utilizes them. They turn big ship props through the water. The transmission handles the engine’s power properly.

These transmissions are workhorses. They are important for relocating heavy lots. They are important for driving big procedure equipment. Their toughness and sturdiness maintain industries running. They are constructed to last under extreme pressure. They supply power where it’s required most.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Solid Shaft High power Transmission gearbox High Torque Industrial Gearbox

Solid Shaft High Power Transmission Gearbox FAQs

What does this industrial gearbox do?

This gearbox moves huge amounts of power. It takes high input speed and torque from a motor. It changes the speed and torque output. The result is strong, slow turning force perfect for heavy machines. Think crushers, large mixers, or conveyors moving tons of material.

How much torque can it handle?

These gearboxes manage extreme torque. They are built for the toughest jobs. The solid steel shafts are key. They don’t bend or twist under heavy strain. The internal gears are hardened steel too. They mesh precisely. This combination transfers massive power reliably. You get consistent performance crushing rock or mixing thick materials.

Why choose solid shafts?

Solid shafts are essential for high torque. Hollow shafts can fail under severe twisting loads. Solid shafts resist this twisting force much better. They provide maximum strength and rigidity. This prevents shaft deflection and bearing overload. Your equipment runs smoother and lasts longer.

Is maintenance difficult?

Maintenance is straightforward. These gearboxes are designed for industrial use. They feature sturdy housings and accessible lubrication points. Regular oil checks and changes are the main tasks. Inspect seals for leaks periodically. Check mounting bolts stay tight. Proper care extends service life significantly. Mounting surfaces matter for alignment and preventing stress.

Can it fit my specific machine?

Yes. These gearboxes are highly customizable. Manufacturers offer different sizes and power ratings. Gear ratios are adjustable to match your speed and torque needs. Input and output shaft dimensions can be modified. Mounting flanges adapt to various setups. Tell us your motor specs and machine requirements. We find the right gearbox solution.

(Solid Shaft High power Transmission gearbox High Torque Industrial Gearbox)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Slow Down Square High Hardness High Precision Aluminum Alloy Gearbox

Holder Block CNC Lathing Distance Place Lab-on-Chip Diagnostic PCR Tests 220V Motor Engine Gear Gearbox Bearing PLC CNC Pump

420685390 CanAm 800cc Gearbox Transmission for Can-am 800 Outlander Renegade 800R ATV UTV 4×4 Body Parts Gearbox 420684780

TQG High Torque Planetary Gearbox Speed Reducer Gear Box For Stepper Motor Transmission Reduction Gearbox

R/S/F/K Series Industrial Helical Gearbox Motors Parallel Shaft Helical-Worm Gearmotors