PRODUCT PARAMETERS

Description

Introduction of RV Worm Gearbox, Self-locking Gearbox, Matching Servo / Stepper Motor Gearbox NEMA34 OEM Automation Equipment Worm Gear Box

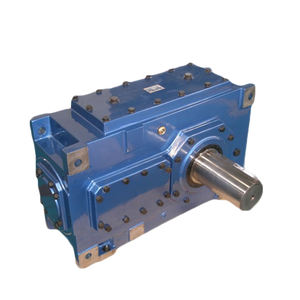

RV Worm Gearbox, Self-locking Gearbox, Matching Servo / Stepper Motor Gearbox NEMA34 OEM Automation Equipment Worm Gear Box, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.RV Worm Gearbox, Self-locking Gearbox, Matching Servo / Stepper Motor Gearbox NEMA34 OEM Automation Equipment Worm Gear Box is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of RV Worm Gearbox, Self-locking Gearbox, Matching Servo / Stepper Motor Gearbox NEMA34 OEM Automation Equipment Worm Gear Box

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(RV Worm Gearbox, Self-locking Gearbox, Matching Servo / Stepper Motor Gearbox NEMA34 OEM Automation Equipment Worm Gear Box)

Specification of RV Worm Gearbox, Self-locking Gearbox, Matching Servo / Stepper Motor Gearbox NEMA34 OEM Automation Equipment Worm Gear Box

The RV Worm Transmission is a self-locking transmission for automation devices. It pairs with servo electric motors and stepper electric motors. It fits NEMA34 designs. This transmission matches OEM applications needing dependability. The self-locking function stops back-driving. This means the outcome shaft holds position when the motor stops. No additional brakes are necessary. This enhances security. It additionally reduces system costs.

This transmission supplies high decrease ratios. Ratios vary from 5:1 to 100:1. You pick the ratio based on your needs. High ratios offer more torque. They allow exact control. This is optimal for slow-moving rate and high force tasks. The portable style saves room in machinery. The real estate is aluminum alloy. This makes it light-weight and corrosion-resistant. Inside, solidified steel gears handle hefty tons. They last long in difficult problems.

Procedure is smooth and silent. The worm equipment design reduces resonance and sound. This matters in noise-sensitive environments. It attaches directly to NEMA34 servo or stepper electric motors. Placing is simple. This accelerates setting up. The gearbox functions reliably in constant procedure. Maintenance is very little.

Use it in conveyor systems, packaging equipments, robot arms, and other automated tools. It handles recurring motions well. OEMs select it for sturdiness and effectiveness.

Secret requirements:

– Decrease Ratios: 5:1, 10:1, 20:1, 30:1, 40:1, 50:1, 60:1, 80:1, 100:1

– Input: NEMA34 servo/stepper motor

– Housing: Light weight aluminum alloy

– Gears: Hardened steel

– Torque Capacity: High torque result (based on ratio).

– Mounting: Requirement bolt patterns for very easy integration.

(RV Worm Gearbox, Self-locking Gearbox, Matching Servo / Stepper Motor Gearbox NEMA34 OEM Automation Equipment Worm Gear Box)

Applications of RV Worm Gearbox, Self-locking Gearbox, Matching Servo / Stepper Motor Gearbox NEMA34 OEM Automation Equipment Worm Gear Box

RV worm gearboxes address troubles in numerous industrial equipments. These transmissions offer high torque outcome. They have a portable layout. This saves space in limited devices formats. The self-locking feature is vital. It stops back-driving. This means the tons won’t push back when the motor quits. It imitates an all-natural brake. Safety improves significantly. Makers hold placement firmly without additional brakes.

These transmissions pair directly with servo motors. They likewise work perfectly with stepper motors. Common sizes consist of NEMA 34. This direct matching simplifies style. It minimizes the requirement for extra couplings. It also decreases assembly time. Setup is faster and much more trustworthy. The transmission mounts right onto the electric motor face.

OEM automation equipment depends greatly on these transmissions. They are discovered inside product packaging devices. They drive conveyor belts accurately. They position robot arms accurately. Material handling systems utilize them thoroughly. They lift, reduced, and move loads exactly. Food handling lines integrate them. They manage blending, filling up, and sorting jobs. Clinical tool suppliers select them for smooth activity control. Their peaceful procedure is a benefit below.

The high reduction proportions are very important. Proportions from 5:1 as much as 100:1 are basic. This enables tiny motors to move hefty tons. It offers fine control over rate and setting. Effectiveness is good for worm drives. Resilience is proven in challenging conditions. They manage dust, dampness, and resonance well. Maintenance needs are reduced. This lowers downtime expenses.

Applications demand integrity and safety. Self-locking worm transmissions deliver both. They are vital for vertical lifts. They safeguard lots on inclined conveyors. They make certain precise stops in assembly terminals. Their capability to hold position without power is crucial. It stops mishaps and item damage. Maker building contractors integrate them for these reasons. Performance and safety and security are the outcomes.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of RV Worm Gearbox, Self-locking Gearbox, Matching Servo / Stepper Motor Gearbox NEMA34 OEM Automation Equipment Worm Gear Box

What makes this gearbox self-locking?

The worm and wheel design creates friction. This friction stops the output shaft from moving backwards. The load cannot drive the motor in reverse. The gearbox holds its position securely without needing brakes. This is essential for safety in lifts or vertical axes.

Which motors fit this gearbox?

It directly connects to NEMA34 servo motors. It also fits NEMA34 stepper motors. The input shaft and bolt pattern match the NEMA34 standard. You get a compact, integrated drive unit. This simplifies your machine design.

How much torque can it handle?

Output torque ratings are high. Exact numbers depend on the specific model. Check the product datasheet for your chosen size. The robust housing and hardened gears handle significant loads. This makes it suitable for demanding automation tasks.

Is it energy efficient?

Worm gearboxes have inherent friction. This means some energy loss occurs. Efficiency is lower than some other gear types. The self-locking benefit often outweighs the efficiency loss. The reliable holding position is the key advantage.

What maintenance does it need?

These gearboxes require minimal upkeep. High-quality lubricant is factory-filled. This lubricant lasts a long time under normal conditions. Check seals periodically for leaks. Replace the lubricant if contamination occurs or after very long service periods.

(RV Worm Gearbox, Self-locking Gearbox, Matching Servo / Stepper Motor Gearbox NEMA34 OEM Automation Equipment Worm Gear Box)

REQUEST A QUOTE

RELATED PRODUCTS

GEXIN High Performance Customized Reducer Agricultural Gearbox Hole In And Axle Out Reducer With Output Flange

Input 1500rpm Output 500rpm Worm RV Gearboxes Speed Reducer Reductor de vdlocidad Washing Machine

synchronizer full set ring for auto manual transmission gearbox for shacman DAYUN FAW siontruk truck 125T-1701150

Wpa Right Angle Foot Mounted Solid Shaft Cast Iron Worm Gear Reducer Chain Drive Gear Box Reduction gearbox For