PRODUCT PARAMETERS

Description

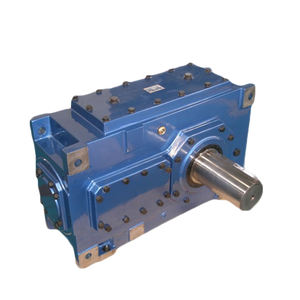

Introduction of Motor Gear Box Transfer Truck Transmission Gearbox

Motor Gear Box Transfer Truck Transmission Gearbox, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.Motor Gear Box Transfer Truck Transmission Gearbox is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of Motor Gear Box Transfer Truck Transmission Gearbox

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(Motor Gear Box Transfer Truck Transmission Gearbox)

Specification of Motor Gear Box Transfer Truck Transmission Gearbox

This Motor Gear Box Transfer Vehicle Transmission Gearbox is constructed difficult. It relocates power from your vehicle’s engine to the wheels dependably. Think about it as the essential muscle mass for heavy hauling and requiring job sites. Stamina and long life are its primary goals.

The core uses solid steel equipments. These gears manage high torque tons without breaking. They punctured resistance smoothly. Precision machining ensures every gear tooth fits flawlessly. This reduces damage. It also lowers sound during procedure. You get peaceful, reliable power transfer.

Robust bearings sustain all revolving parts within. These bearings take the anxiety. They permit shafts to rotate openly under hefty pressure. A strong steel housing confines whatever. This real estate safeguards the gears and bearings from dust, water, and influences. It keeps the inner components risk-free and clean.

Oil lubrication is crucial. Special oil moves constantly over the gears and bearings. This oil lowers friction. It stops overheating. It carries away harmful steel fragments. Routine oil checks and changes are crucial. They maintain the gearbox running smoothly for many years.

Various equipment ratios are offered. These ratios allow you match the gearbox flawlessly to your truck’s job. Required huge pulling power at reduced rates? There’s a ratio for that. Need reliable cruising for freeway miles? Another ratio manages that. Choose the ratio that fits your details hauling demands.

Trick specs specify its performance. Torque capability is high. Input and output shaft dimensions are common for very easy fitting. Placing points are strong and uncomplicated. Weight is kept manageable for the power it provides. Seals are high-quality. They avoid oil leaks accurately. This transmission links directly to your truck’s drivetrain. It functions flawlessly with the engine and axles. It’s produced transfer trucks doing serious job day after day. You can depend on its performance. It gets the job done.

(Motor Gear Box Transfer Truck Transmission Gearbox)

Applications of Motor Gear Box Transfer Truck Transmission Gearbox

An electric motor transmission is an essential element in lots of commercial equipments. It readjusts rate and torque from the motor. Transfer trucks depend heavily on these gearboxes. The transmission gearbox relocates power from the engine to the wheels. This permits heavy tons to be carried efficiently. Transfer vehicles operate in demanding atmospheres. Construction websites use them daily. They haul materials like crushed rock or steel beam of lights. The gearbox deals with harsh terrain conveniently. It provides reliable power for high slopes. Mining procedures depend upon these vehicles also. They bring large lots of ore or planet. The gearbox withstands constant anxiety underground. It makes certain constant motion in constrained spaces. Agriculture gain from transfer trucks as well. They transport harvests across large farms. The gearbox handles muddy fields. It keeps traction on irregular ground. Logistics firms make use of transfer trucks thoroughly. They relocate products in between storehouses and ports. The gearbox handles stop-and-go city website traffic. It prevents jerky starts that damage cargo. Factory employ these vehicles inside. They shift raw materials around factories. The gearbox supports accurate lots positioning. It functions smoothly with training tools. Emergency services use specialized transfer trucks. Fire engine or rescue vehicles require instant power. The gearbox responds promptly to throttle modifications. It supplies high torque for rapid velocity. Upkeep is straightforward for these transmissions. They have resilient seals versus dirt and moisture. Lubrication intervals are long. This lowers downtime for drivers. Gas performance is another benefit. Modern gearboxes maximize engine power. They reduced functional costs dramatically. Safety and security functions are integrated too. Transmissions consist of overload security systems. These prevent damage during severe use. Operators count on the dependability of these devices. Efficiency remains regular in warmth or cold.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Motor Gear Box Transfer Truck Transmission Gearbox

Motor Gear Box Transfer Truck Transmission Gearbox FAQs

What exactly does this gearbox do? It moves power from your truck’s engine to the wheels. It lets you shift between different gear ratios. You need this for handling different speeds and loads. The transfer part splits power between front and rear axles too. This gives you four-wheel drive when necessary.

How can I tell if my gearbox is wearing out? Watch for specific signs. Listen for grinding or whining noises during shifting. Notice if gears slip out of position unexpectedly. Check for leaks underneath the truck. Feel for vibrations coming through the gear shifter. Difficulty engaging gears is another warning sign. Don’t ignore these problems.

How often should I maintain this gearbox? Check the oil level regularly. Look at your truck’s owner manual for the exact schedule. Change the gear oil completely at the intervals specified. This is usually every 30,000 to 60,000 miles. Inspect seals and gaskets during oil changes. Look for leaks or damage.

What kind of oil works best? Only use the oil recommended by the manufacturer. This information is in your owner’s manual. Using the wrong oil causes serious damage. Gear oil is thicker than engine oil. It needs special additives. These protect the gears under heavy pressure. Wrong oil leads to poor shifting and gear damage.

When should I think about rebuilding or replacing it? Consider this after major failures. Examples are broken gears or seized bearings. Constant noise or shifting trouble after maintenance means problems. Leaks you can’t fix are another sign. Severe damage makes rebuilding expensive. Sometimes replacement is the smarter choice.

(Motor Gear Box Transfer Truck Transmission Gearbox)

REQUEST A QUOTE

RELATED PRODUCTS

HXMT Helical Gear Nema23 Planetary Gearbox From China Factory/

Transmission gearbox for chevrolet sail 1.4 SH12M5A1-1701001 Rebuilt Transmissions

420685390 CanAm 800cc Gearbox Transmission for Can-am 800 Outlander Renegade 800R ATV UTV 4×4 Body Parts Gearbox 420684780

Agricultural Gearboxes Agriculture Bevel Gearbox For Reducer T Right Angle Pto For Agricultural gearbox

factory wholes the other auto transmission TOYOTta RAV4 CAMRY TRANSMISSION AUTOMATIC GEARBOX LOW MILES