PRODUCT PARAMETERS

Description

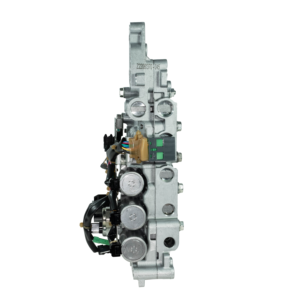

Introduction of MaTech Factory Custom Gravity Cast Sand Casting Industrial Gearbox Housing Agricultural machinery parts

MaTech Factory Custom Gravity Cast Sand Casting Industrial Gearbox Housing Agricultural machinery parts, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.MaTech Factory Custom Gravity Cast Sand Casting Industrial Gearbox Housing Agricultural machinery parts is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of MaTech Factory Custom Gravity Cast Sand Casting Industrial Gearbox Housing Agricultural machinery parts

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(MaTech Factory Custom Gravity Cast Sand Casting Industrial Gearbox Housing Agricultural machinery parts)

Specification of MaTech Factory Custom Gravity Cast Sand Casting Industrial Gearbox Housing Agricultural machinery parts

MaTech Factory Custom Gravity Cast Sand Casting Industrial Gearbox Housing Agricultural machinery parts are designed and produced to meet the highest standards of quality and durability in the industry. Our products undergo rigorous testing and inspection before being shipped out to ensure that they meet or exceed customer expectations.

The materials used in our manufacturing process are carefully selected to ensure maximum strength, wear resistance, and longevity. We use high-quality cast iron, which is known for its strength and durability. The components are also carefully machined to provide precise fit and operation.

In addition to their high-quality construction, our products are also designed to be easy to maintain and repair. This is achieved through the use of durable materials and precision-engineered components that allow for quick and efficient repairs when needed.

Our Custom Gravity Cast Sand casting Industrial Gearbox Housing Agricultural machinery parts can be customized to meet specific requirements. This includes adding or removing components, changing the shape or size of the housing, or modifying the function of the gears.

Overall, MaTech Factory Custom Gravity Cast Sand Casting Industrial Gearbox Housing Agricultural machinery parts are an excellent choice for anyone looking for reliable and high-quality agricultural machinery parts. With our attention to detail and commitment to excellence, we are confident that our products will meet and exceed your expectations.

(MaTech Factory Custom Gravity Cast Sand Casting Industrial Gearbox Housing Agricultural machinery parts)

Applications of MaTech Factory Custom Gravity Cast Sand Casting Industrial Gearbox Housing Agricultural machinery parts

MaTech Factory’s custom gravity cast sand casting industrial gearbox housing agricultural machinery parts offer precision manufacturing solutions for a wide range of applications.

Our industry experts use the latest technology in machine design and material science to create high-quality, durable, and cost-effective gearboxes housing that meets the exacting requirements of your specific machinery. Whether you need a simple bearing housing or complex, our team has the expertise and resources to provide a customized solution that will exceed your expectations.

One of the key benefits of using MaTech Factory’s custom gravity cast sand casting industrial gearbox housing agricultural machinery parts is their ability to withstand extreme conditions. Our equipment is designed with materials that can withstand temperatures up to 450°C, making it suitable for use in demanding environments such as harsh weather conditions and high-temperature processes.

Another advantage of our products is their durability and reliability. Our gearboxes housing components are made from high-strength materials that resist wear and tear, ensuring that they will continue to function smoothly over time. Additionally, our attention to detail ensures that every component is crafted to the highest standards, resulting in a product that performs flawlessly in even the toughest applications.

In addition to these benefits, our custom gravity cast sand casting industrial gearbox housing agricultural machinery parts are also easy to install and maintain. With clear, concise instructions and a user-friendly interface, our team can help you get started quickly and easily. And, because we offer ongoing support and maintenance services, you can rest assured that your equipment will continue to operate at its best.

In conclusion, MaTech Factory’s custom gravity cast sand casting industrial gearbox housing agricultural machinery parts are a great choice for any application where precision and durability are essential. Our experienced professionals and advanced technology make us the go-to provider for all your machinery needs. Contact us today to learn more about how we can help you improve your efficiency and productivity.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of MaTech Factory Custom Gravity Cast Sand Casting Industrial Gearbox Housing Agricultural machinery parts

1. What is gravity casting and how does it differ from other casting methods?

Gravity casting, also known as die casting, uses the weight of molten metal to shape the part during casting. This method produces highly accurate shapes that can be made with high precision.

2. How long does it take for a gravity cast to complete?

The time it takes for a gravity cast depends on several factors such as the size of the part, the type of material being used, and the skill level of the operator. On average, a gravity cast can take anywhere from a few hours to a day or more, depending on the circumstances.

3. Can gravity casting be used for both casting parts and production lines?

Yes, gravity casting can be used in both casting parts and production lines. It is a versatile casting technique that can be used to produce high-quality parts quickly and efficiently.

4. What are some common types of industrial gears and what materials do they typically require for casting?

Common types of industrial gears include spur gears, helical gears, and ball bearings. The materials required for casting these gears can vary depending on their design and intended use.

5. What are some advantages of using gravity casting over other casting methods?

One advantage of gravity casting is its accuracy and consistency. Because gravity casting involves the weight of molten metal, it produces highly accurate shapes that are difficult to achieve with other casting methods. Additionally, gravity casting can be done at a lower temperature, which allows for greater flexibility and reduced waste.

(MaTech Factory Custom Gravity Cast Sand Casting Industrial Gearbox Housing Agricultural machinery parts)

REQUEST A QUOTE

RELATED PRODUCTS

GEXIN High Performance Gearbox RV Reducer Factory Direct Customized Hole In And Axle Out Reducer For Large Equipment

TILI Planetary Reducer Equipped Servo Motor Original 400W Precision Gearbox 60mm Square Output Flange Gearbox

09G TF-60SN Automatic Transmission Gearbox Overhaul kit Seal Kit for AUDI VW ZG12993001

Helical Gears Flange Output High Precision Series Planetary Gearbox Reducer