PRODUCT PARAMETERS

Description

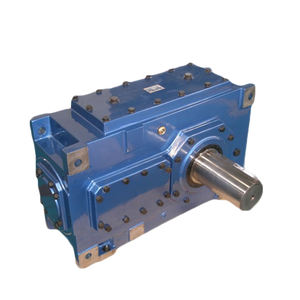

Introduction of Manufacture zq cylindrical reduction gearbox 1450rpm zq250 shaft gearbox with speed ratio 8.23

Manufacture zq cylindrical reduction gearbox 1450rpm zq250 shaft gearbox with speed ratio 8.23, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.Manufacture zq cylindrical reduction gearbox 1450rpm zq250 shaft gearbox with speed ratio 8.23 is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of Manufacture zq cylindrical reduction gearbox 1450rpm zq250 shaft gearbox with speed ratio 8.23

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(Manufacture zq cylindrical reduction gearbox 1450rpm zq250 shaft gearbox with speed ratio 8.23)

Specification of Manufacture zq cylindrical reduction gearbox 1450rpm zq250 shaft gearbox with speed ratio 8.23

The ZQ round decrease transmission version ZQ250 is made for durable commercial applications. This transmission runs at 1450 RPM input rate with a rate ratio of 8.23. It ensures effective power transmission in between equipment elements. The portable cylindrical style enables easy integration into systems with restricted area.

The gearbox makes use of hardened steel equipments for durability under high tons. The equipments undertake precision grinding to reduce sound and vibration. Lubrication is maximized to lower rubbing and expand service life. The real estate is made from cast iron for toughness and resistance to use. Secured bearings prevent contamination from dust or dampness.

Input and result shafts are straightened flat for uncomplicated setup. The input shaft size is 35mm. The outcome shaft diameter is 45mm. Both shafts support radial and axial tons. Flange-mounted or foot-mounted configurations are offered. This flexibility suits different devices formats.

The ZQ250 handles a maximum torque ability of 2500 Nm. Thermal effectiveness goes beyond 96% under normal operating conditions. Warmth dissipation is improved through ribbed real estate surfaces. Maintenance periods are expanded because of robust interior components. Oil seals prevent leakages also in high-temperature settings.

This gearbox works with motors, conveyors, mixers, and crushers. Usual applications include mining, building and construction, and product handling. Rate reduction stabilizes result for specific control of machinery. The 8.23 proportion equilibriums torque and rate for medium to heavy tons.

Setup calls for aligning the gearbox with connected devices. Appropriate positioning protects against early endure shafts and gears. Lubricant levels have to be checked before first procedure. Normal examinations guarantee optimal efficiency with time.

The ZQ250 satisfies industry criteria for safety and security and integrity. Modification alternatives include various shaft sizes or placing placements. Technical support is offered for combination obstacles. Spare components come for quick fixings.

This transmission reduces downtime sought after settings. Its style prioritizes straightforward maintenance. Efficiency continues to be regular throughout differing operating temperatures. The mix of toughness and efficiency makes it a practical option for industrial setups.

(Manufacture zq cylindrical reduction gearbox 1450rpm zq250 shaft gearbox with speed ratio 8.23)

Applications of Manufacture zq cylindrical reduction gearbox 1450rpm zq250 shaft gearbox with speed ratio 8.23

The Manufacture ZQ round decrease gearbox 1450rpm ZQ250 shaft transmission with a rate proportion of 8.23 is made to reduce electric motor rate and rise torque for industrial machinery. It handles high input rates of 1450rpm and supplies reliable power transfer through its round equipment design. The rate ratio of 8.23 makes sure outcome speed is exactly adapted to match functional demands. This gearbox matches heavy-duty applications due to its resilient construct and effective performance.

Usual applications consist of conveyor systems in production and logistics. The transmission offers regular torque to maintain products moving efficiently on assembly line. It is used in mining tools like crushers and grinders. The durable building and construction stands up to extreme environments and heavy lots. Building and construction equipment such as cranes and winches count on this gearbox for training and relocating products. The high torque output supports secure procedure under demanding problems.

In farming, the gearbox powers irrigation pumps and grain handling equipments. Its capability to handle variable tons makes it excellent for farming devices. Food processing plants use it in mixers and packaging lines. The gearbox’s sealed design protects against contamination from dirt or moisture. Marine sectors mount it in ship winches and cargo handling systems. The corrosion-resistant materials make sure longevity in salty environments.

The ZQ250 version includes a small layout for easy combination right into limited areas. Upkeep is simple as a result of available elements and easy lubrication requirements. Factories favor this gearbox for its versatility throughout different equipments. It works with electric motors, diesel engines, or hydraulic systems. The transmission decreases energy consumption by optimizing power transmission. Industries choose it for its balance of performance, durability, and cost-effectiveness.

Mining operations benefit from its shock-resistant equipments during rock crushing. Building jobs utilize it to power concrete mixers and excavators. Agricultural machinery depends on it for tasks like raking and harvesting. The gearbox’s versatility makes it a key part in lots of industries. Its layout focuses on smooth procedure and minimal resonance. Operators value the low noise degrees during expanded use.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Manufacture zq cylindrical reduction gearbox 1450rpm zq250 shaft gearbox with speed ratio 8.23

What is the ZQ250 cylindrical reduction gearbox mainly used for? The ZQ250 gearbox reduces motor speed to match equipment needs. It works in industries like mining, construction, or conveyor systems. The design handles heavy loads efficiently. It suits machines requiring stable torque and controlled speed.

What does the speed ratio 8.23 mean? The speed ratio shows how much the input speed decreases. If the motor runs at 1450rpm, the output drops to roughly 176rpm (1450 divided by 8.23). This ratio balances speed reduction and torque increase. It ensures equipment runs smoothly under load.

Can the ZQ250 handle high-stress applications? Yes. The gearbox uses cast iron housing and hardened steel gears. These materials resist wear and heavy pressure. It operates reliably in tough conditions like mining or heavy machinery. Regular maintenance extends its lifespan under stress.

How often should the gearbox be maintained? Check oil levels every 500 hours. Replace lubricant every 3,000 hours or as the environment demands. Inspect gears and seals for wear during oil changes. Clean the exterior to prevent dirt buildup. Proper care reduces breakdowns.

What are the installation requirements? Align the gearbox shaft with the motor shaft precisely. Secure the unit on a flat, stable base. Ensure bolts are tight but avoid over-tightening. Verify lubrication before starting. Incorrect installation causes vibration or damage. Follow the manual for specific torque settings.

(Manufacture zq cylindrical reduction gearbox 1450rpm zq250 shaft gearbox with speed ratio 8.23)

REQUEST A QUOTE

RELATED PRODUCTS

Original VT2 CVT Automatic Transmission Assy Gearbox for Geely Emgrand EC7 Condition Used/New

mining dump truck chassis parts 7DS180 gearbox 8DS240A accessories 9JS200TA 1701050 1701054 1701055 1701053 1701048 1701049

high precision speed reducer planetary gear reducer gearbox for nema 34 stepper motor

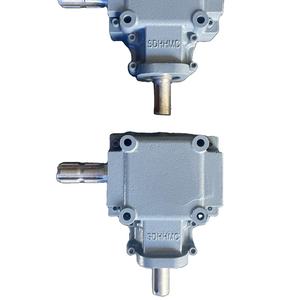

Wpa Right Angle Foot Mounted Solid Shaft Cast Iron Worm Gear Reducer Chain Drive Gear Box Reduction gearbox For

Factory Direct New Modular Belt Conveyor Flat Top Straight Design Food Grade Polyester Fruits Vegetables Core Motor Gearbox Food