PRODUCT PARAMETERS

Description

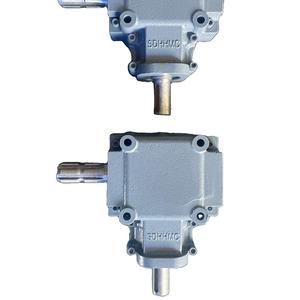

Introduction of geared motors gearbox reducer drive power transmission shaft gearbox Helical Worm Gear Reducer Motor

geared motors gearbox reducer drive power transmission shaft gearbox Helical Worm Gear Reducer Motor, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.geared motors gearbox reducer drive power transmission shaft gearbox Helical Worm Gear Reducer Motor is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of geared motors gearbox reducer drive power transmission shaft gearbox Helical Worm Gear Reducer Motor

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(geared motors gearbox reducer drive power transmission shaft gearbox Helical Worm Gear Reducer Motor)

Specification of geared motors gearbox reducer drive power transmission shaft gearbox Helical Worm Gear Reducer Motor

The Helical Worm Gear Reducer Motor is a highly efficient and reliable solution for power transmission applications, designed to deliver optimal performance in a wide range of industrial settings. This gearbox reducer combines the advantages of helical and worm gear technologies, offering a compact, durable, and energy-efficient design. It is ideal for applications requiring high torque output, smooth operation, and precise speed reduction.

The gearbox is constructed with high-quality materials, ensuring exceptional durability and resistance to wear and tear. The helical gears provide superior load-bearing capacity, reduced noise levels, and enhanced efficiency, while the worm gear mechanism ensures a high reduction ratio and self-locking capability. This combination makes the reducer suitable for heavy-duty applications, such as conveyor systems, mixers, crushers, and lifting equipment.

The motor is available in various power ratings, ranging from 0.12 kW to 15 kW, and can accommodate input speeds up to 1500 RPM. The reduction ratio options are extensive, typically ranging from 5:1 to 100:1, allowing for precise speed control and torque adjustment to meet specific operational requirements. The output shaft is designed to handle high radial and axial loads, ensuring reliable performance under demanding conditions.

The Helical Worm Gear Reducer Motor features a robust housing made of cast iron or aluminum alloy, providing excellent heat dissipation and protection against environmental factors. It is also designed for easy installation and maintenance, with options for foot-mounted, flange-mounted, or shaft-mounted configurations. The gearbox is compatible with various motor types, including AC, DC, and servo motors, making it a versatile choice for diverse applications.

With its compact design, high efficiency, and reliable performance, the Helical Worm Gear Reducer Motor is an excellent choice for industries such as manufacturing, food processing, packaging, and material handling. It ensures smooth power transmission, reduced energy consumption, and extended service life, making it a cost-effective solution for your power transmission needs.

(geared motors gearbox reducer drive power transmission shaft gearbox Helical Worm Gear Reducer Motor)

Applications of geared motors gearbox reducer drive power transmission shaft gearbox Helical Worm Gear Reducer Motor

The Applications of Geared Motors, Gearbox Reducers, Drive Power Transmission Shafts, and Helical Worm Gear Reducer Motors are vast and diverse, spanning across numerous industries where precision, efficiency, and reliability in power transmission are essential. These components are integral to systems that require controlled speed, torque, and motion, making them indispensable in modern machinery and automation.

Geared motors and gearbox reducers are commonly used in industrial automation, where they provide the necessary torque and speed reduction for conveyor belts, packaging machines, and robotic arms. Their ability to handle heavy loads while maintaining precise control ensures smooth operation in manufacturing processes. In the food and beverage industry, these components are utilized in mixers, conveyors, and bottling lines, where hygiene and durability are critical.

Drive power transmission shafts play a pivotal role in transferring mechanical power from one component to another, often in applications like agricultural machinery, construction equipment, and automotive systems. They ensure seamless power delivery, even in challenging environments, by connecting engines, motors, and other mechanical parts.

Helical worm gear reducer motors are particularly valued for their compact design, high efficiency, and ability to handle high torque loads. These motors are widely used in material handling equipment, such as cranes, hoists, and elevators, where space constraints and load-bearing capacity are key considerations. Additionally, they are employed in HVAC systems, where their quiet operation and energy efficiency contribute to optimal performance.

In the renewable energy sector, these components are crucial for wind turbines and solar tracking systems, enabling precise movement and energy conversion. Their durability and low maintenance requirements make them ideal for such demanding applications.

Overall, geared motors, gearbox reducers, drive power transmission shafts, and helical worm gear reducer motors are foundational to modern engineering, driving innovation and efficiency across industries. Their versatility and reliability ensure they remain at the forefront of power transmission technology.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of geared motors gearbox reducer drive power transmission shaft gearbox Helical Worm Gear Reducer Motor

A geared motor, also known as a gearbox reducer, is a crucial component in power transmission systems, combining a motor and a gearbox to deliver efficient torque and speed control. Helical worm gear reducers, in particular, are widely used for their compact design, high efficiency, and durability. Here are five frequently asked questions about helical worm gear reducers:

1. **What is a helical worm gear reducer?**

A helical worm gear reducer is a type of gearbox that combines helical gears and a worm gear mechanism. The helical gears provide smooth and quiet operation, while the worm gear offers high reduction ratios and excellent torque transmission. This combination makes it ideal for applications requiring precise speed control and high load capacity.

2. **What are the advantages of using a helical worm gear reducer?**

Helical worm gear reducers are known for their compact design, high efficiency, and ability to handle heavy loads. They operate quietly, reduce vibration, and provide excellent torque output. Additionally, their self-locking feature ensures safety in applications where back-driving is a concern.

3. **Where are helical worm gear reducers commonly used?**

These gear reducers are widely used in industries such as manufacturing, material handling, food processing, and packaging. They are ideal for conveyor systems, mixers, crushers, and other machinery requiring precise speed reduction and high torque.

4. **How do I select the right helical worm gear reducer for my application?**

To choose the right reducer, consider factors such as required torque, speed, input power, and mounting configuration. It’s also essential to evaluate the operating environment, including temperature, humidity, and load conditions, to ensure optimal performance and longevity.

5. **What maintenance is required for a helical worm gear reducer?**

Regular maintenance is key to ensuring the longevity of a helical worm gear reducer. This includes periodic lubrication, checking for wear and tear, and ensuring proper alignment. Most helical worm gear reducers are designed for low maintenance, but routine inspections can prevent unexpected downtime.

Helical worm gear reducers are a reliable and efficient solution for power transmission needs, offering a balance of performance, durability, and versatility. Whether you’re upgrading existing machinery or designing a new system, these gear reducers provide the precision and power required for demanding applications.

(geared motors gearbox reducer drive power transmission shaft gearbox Helical Worm Gear Reducer Motor)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Slow Down Square High Hardness High Precision Aluminum Alloy Gearbox

25-300 HP cheap tractor gearbox in Weifang, Shandong, China Assembly parts

Sail Gearbox 9016650 Transmission Gearbox for Chevrolet Sail 1.2MT

R/S/F/K Series Industrial Helical Gearbox Motors Parallel Shaft Helical-Worm Gearmotors

S Series Helical Gearbox Right Angle Worm Transmission Gearbox With High Overload Bearing Capacity