PRODUCT PARAMETERS

Description

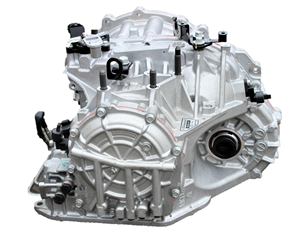

Introduction of Gearbox Gear For Automotive Parts

Gearbox Gear For Automotive Parts, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.Gearbox Gear For Automotive Parts is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of Gearbox Gear For Automotive Parts

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(Gearbox Gear For Automotive Parts)

Specification of Gearbox Gear For Automotive Parts

Gearbox equipments are crucial components inside your vehicle’s transmission. They handle engine power and move it to the wheels. These gears need to be extremely strong and trustworthy. We make them from special steel alloys. These alloys offer the required sturdiness and resistance to put on. Typical choices include carburizing qualities. These grades obtain dealt with to make the surface added tough.

The manufacturing process is precise. We begin by creating or reducing the gear form from steel bars. This develops the standard equipment kind. Next comes machining. This step fine-tunes the equipment teeth to exact sizes and shapes. Tooth form is vital. It impacts just how smoothly the equipments fit together and just how silent the transmission runs. Usual tooth designs include spur and helical kinds. Helical teeth run quieter.

Warm treatment is vital. It makes the gears hard enough to last. We make use of procedures like carburizing or induction hardening. Carburizing includes carbon to the equipment surface. After that we quench it. This creates an exceptionally tough outer layer. The core stays challenging. This mix prevents fracturing under hefty tons. Induction setting heats up simply the tooth surface swiftly. Then we cool it quick. This also makes the surface area extremely hard.

Precision grinding follows warmth therapy. This action makes sure every tooth has the precise right form and finish. Grinding gets rid of tiny distortions from heating. It attains exact measurements. Tolerances are tight. We determine in thousandths of a millimeter. Smooth tooth surface areas lower friction. This reduces power loss and warmth buildup.

Quality assurance occurs throughout. We evaluate products prior to production. We inspect dimensions throughout machining. Finished gears go through rigorous testing. We search for surface area flaws. We verify hardness levels. We examine tooth profiles carefully. Some equipments get checked for noise and resilience. This guarantees they execute accurately in your automobile for a very long time. Correct lubrication is likewise crucial. The best oil protects the equipments and keeps them running smoothly.

(Gearbox Gear For Automotive Parts)

Applications of Gearbox Gear For Automotive Parts

Transmission gears are vital parts in vehicles. They handle engine power properly. Gears transfer engine power to the wheels. This makes the automobile move. Different driving circumstances need various power degrees. Gears handle this. They allow the engine run well. The engine stays reliable.

Gears change rate and force. They trade rotation speed for transforming force. This is torque. Lower equipments offer high torque. This is important for beginning. It helps with acceleration. It aids climbing up hills. Greater gears use much less torque. They enable greater speeds. The engine does not strain. Fuel performance boosts.

Transmission gears select these various ratios. Motorists alter equipments manually. Automatic transmissions change immediately. Both systems rely on strong, exact equipments. Equipments mesh with each other smoothly. They move power accurately. Longevity issues. Equipments withstand consistent anxiety. Correct lubrication stops wear. It lowers friction warm.

Differentials also make use of equipments. They divided engine power between wheels. Tires turn at different speeds throughout turns. The differential enables this. It guarantees stable cornering. Four-wheel-drive cars have transfer situations. These systems use equipments as well. They send out power to front and back axles. Grip improves on unsafe surfaces.

Reverse equipment is one more key application. It changes the result direction. The cars and truck relocates backwards. Gears enable this essential function. All these equipment systems work together. They change raw engine power into controlled motion. Cars speed up smoothly. They climb up inclines. They travel efficiently. Equipments make modern driving feasible. They are fundamental automobile parts.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Gearbox Gear For Automotive Parts

Gearbox Gears: Your Top 5 Questions Answered

What tells me my car’s gearbox gears might be bad?

Listen for strange noises. Grinding or whining sounds when shifting gears are big clues. You might feel rough shifting too. Sometimes the car hesitates or slips out of gear. These signs mean get it checked now. Ignoring them causes worse damage.

How long should gearbox gears usually last?

Good gears last a long time. Think 100,000 miles or more with proper care. But it depends. Hard driving, like constant towing or racing, wears them faster. Regular maintenance is key. Bad fluid or missed services shortens their life a lot.

Can I replace just one damaged gear?

Usually not. Fixing one gear often means opening the whole gearbox. This is expensive labor. Plus, other gears might be worn too. Mechanics typically recommend replacing the whole gear set or getting a rebuilt unit. This ensures everything works together smoothly.

What’s the difference between cheap and premium gear sets?

Cheap gears save money upfront. But they might use weaker materials or less precise cutting. Premium gears use stronger steel alloys. They have better heat treatment and finer machining. This means they handle power better, last longer, and run quieter. You pay more, but get better performance and durability.

How can I make my gearbox gears last longer?

Change your transmission fluid regularly. Use the exact type your carmaker specifies. Avoid rough gear changes and aggressive driving. Don’t overload your car or tow beyond its limit. Get strange noises or shifting checked immediately. Small problems become big, expensive ones fast.

(Gearbox Gear For Automotive Parts)

REQUEST A QUOTE

RELATED PRODUCTS

China car Gearbox For CHERY QQ 372/472 Automotive Transmission Parts

Gearbox

Factory Supply BX Series Planetary Gearbox Gear Motor with High Reduction Ratio and Efficiency

Factory Direct s Whole Ring Gear Gearbox

Solid Shaft High power Transmission gearbox High Torque Industrial Gearbox