PRODUCT PARAMETERS

Description

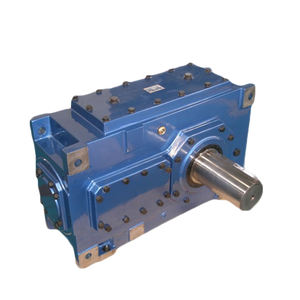

Introduction of Differential Gearbox Motor Electric Tricycle Four-Wheel Drum Brake Rear Axle for club car

Differential Gearbox Motor Electric Tricycle Four-Wheel Drum Brake Rear Axle for club car, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.Differential Gearbox Motor Electric Tricycle Four-Wheel Drum Brake Rear Axle for club car is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of Differential Gearbox Motor Electric Tricycle Four-Wheel Drum Brake Rear Axle for club car

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(Differential Gearbox Motor Electric Tricycle Four-Wheel Drum Brake Rear Axle for club car)

Specification of Differential Gearbox Motor Electric Tricycle Four-Wheel Drum Brake Rear Axle for club car

The differential transmission electric motor electric tricycle four-wheel drum brake back axle is created for Club Automobile designs. It gives trustworthy efficiency for electrical tricycles used in transport or energy jobs. The axle incorporates a differential gearbox system. This enables smooth switching on varied terrain. It makes certain power circulation between wheels reduces wheel slippage enhances grip. The electric motor operates on a standard voltage array compatible with the majority of electrical tricycle setups. It delivers regular torque sustains steady acceleration under lots.

The transmission utilizes set steel gears. These manage high stress last longer under heavy use. The drum brake system uses strong quiting power. It functions well in damp or completely dry conditions requires marginal upkeep. The brake shoes are made from heat-resistant products. This avoids overheating throughout prolonged usage extends part life. The axle housing is built from durable steel. It stands up to deterioration withstands effects from rough roadways.

The rear axle assembly includes pre-installed bearings. These minimize friction make sure smooth turning. The axle length fits typical Club Auto frameworks. Setup is uncomplicated usages common devices. The style consists of installing points for motors or batteries. This simplifies personalization for various arrangements. The differential device balances power in between wheels during turns. This prevents tire wear boosts managing stability.

The electric motor is ranked for continuous procedure. It does not overheat throughout prolonged trips. The gear ratio is optimized for low-speed torque. This is excellent for climbing up hillsides bring hefty lots. The drum brakes are self-adjusting. They preserve constant efficiency without hand-operated calibration. The axle comes pre-greased. This minimizes first setup time makes sure correct lubrication.

The item is evaluated for sturdiness fulfills market safety and security criteria. It works with Club Vehicle designs from 2015 forward. Replacement components are widely available. The axle sustains an optimum load capability of 1200 extra pounds. This suits commercial or personal usage. Guarantee insurance coverage includes issues in materials or handiwork. Technical assistance is offered installation or troubleshooting.

(Differential Gearbox Motor Electric Tricycle Four-Wheel Drum Brake Rear Axle for club car)

Applications of Differential Gearbox Motor Electric Tricycle Four-Wheel Drum Brake Rear Axle for club car

The differential transmission electric motor electrical tricycle four-wheel drum brake rear axle is made for Club Automobile applications. This system incorporates essential functions to provide efficiency in utility lorries, cargo transportation, and guest carriers. The differential gearbox guarantees smooth power circulation between wheels. This permits wheels to revolve at different speeds during turns. It minimizes tire wear and enhances taking care of on uneven surfaces. The electrical motor supplies consistent torque. It sustains consistent acceleration and reliable energy usage. This makes it optimal for stop-start operations in city locations or hilly terrains.

The four-wheel drum brake arrangement boosts safety. Drum brakes are reputable in wet or dirty problems. They require minimal maintenance compared to disc brakes. The rear axle is built with sturdy materials. It endures high tons without flexing or buckling. This durability matches industrial settings, resorts, and universities where automobiles run daily. The axle’s layout decreases resonance. This makes certain a secure trip even when bring hefty cargo or several passengers.

The electrical motor integrates flawlessly with the differential transmission. This pairing enhances battery life. Operators benefit from longer runtimes in between charges. The system works quietly. It lowers sound pollution in crowded settings like parks or occasion locations. The drum brakes react quickly to pedal input. Chauffeurs preserve control throughout sudden quits. This is vital in areas with pedestrian website traffic.

The back axle’s compact framework fits common Club Auto chassis. Setup is straightforward. No major adjustments are needed. The elements withstand corrosion and rust. This expands the item’s lifespan in exterior or humid climates. Regular checks concentrate on bolt tightness and lubrication. Maintenance prices stay reduced over time.

Personalization alternatives consist of gear proportions and electric motor power degrees. Individuals customize the system to match load capacity or terrain requirements. The differential gearbox protects against wheel slippage on loosened gravel or mud. This keeps the automobile moving on without losing grip. The drum brakes dissipate warm properly. They stay clear of overheating during extended use. This reliability makes certain nonstop operation popular jobs like delivery services or waste collection. The mix of these features produces a durable option for industrial and recreational demands.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Differential Gearbox Motor Electric Tricycle Four-Wheel Drum Brake Rear Axle for club car

What is the differential gearbox motor electric tricycle rear axle used for? This axle is designed for Club Car electric tricycles. It combines a motor, gearbox, and drum brake system. It transfers power to the wheels smoothly. It handles turns better than solid axles. It ensures stable performance on uneven terrain.

Why choose a differential gearbox over a standard axle? The differential gearbox lets wheels rotate at different speeds. This prevents wheel slippage during turns. It reduces tire wear. It improves traction on wet or loose surfaces. It enhances control when carrying heavy loads. It works well for commercial or personal use.

Is this rear axle compatible with all Club Car models? Check the axle’s dimensions and mounting points. It fits most Club Car electric tricycles made after 2015. Verify the motor voltage matches your vehicle’s system. Consult the product manual or contact the seller for confirmation. Modifications might be needed for older models.

How do I maintain the drum brake system? Inspect brake shoes every six months. Replace them if worn past 3mm. Clean dust from the drum regularly. Adjust the brake cable tension if braking feels weak. Lubricate pivot points with high-temperature grease. Avoid water exposure to prevent rust. Test brakes after maintenance.

What makes the four-wheel drum brake system reliable? Drum brakes resist heat buildup during frequent stops. They provide consistent stopping power. They require less adjustment than disc brakes. They protect against debris in off-road conditions. They last longer under heavy loads. They suit low-speed vehicles like electric tricycles.

(Differential Gearbox Motor Electric Tricycle Four-Wheel Drum Brake Rear Axle for club car)

REQUEST A QUOTE

RELATED PRODUCTS

China Car Gearbox for Geely 160G 1.5 1.3 gearbox Auto Transmission Parts

50mm planetary gearbox with 50srz high-speed BLDC motor 35W 12v24v brushless DC speed regulating motor

Completely New Transmission Gearbox Assembly 5T15C 5MTT155 for DFM Joyear X5 S500

TQG High Torque Planetary Gearbox Speed Reducer Gear Box For Stepper Motor Transmission Reduction Gearbox

TILI F Series FA Type Heavy Duty Transmission Part Helical Gearbox Electric Parallel Shaft Speed Reducer