PRODUCT PARAMETERS

Description

Introduction of Mechanical Transmission Gearbox

Mechanical Transmission Gearbox, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.Mechanical Transmission Gearbox is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of Mechanical Transmission Gearbox

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

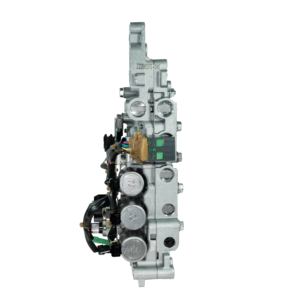

(Mechanical Transmission Gearbox)

Specification of Mechanical Transmission Gearbox

Mechanical transmission gearboxes relocate power from engines or motors to where it’s required. They change rate and torque. These units are important for machinery procedure.

Gearboxes make use of strong materials. Gears and shafts are typically set steel. Real estates are cast iron or aluminum. This makes them difficult and resilient. Bearings support the rotating components. Seals maintain lube inside and dust exterior.

Various gear kinds are common. Spur equipments are easy and efficient. Helical gears run smoother and quieter. Bevel gears change the instructions of power flow. Worm gears supply high reduction ratios. Planetary gears handle really high loads in small rooms.

Gearbox specifications are essential. Input and output shaft dimensions have to match your tools. Rated torque shows the maximum twisting force the transmission can take care of continually. Service factors account for shock loads or severe conditions. Horse power rankings associate with the motor driving the system.

Rate decrease proportions are vital. A 10:1 ratio indicates the outcome shaft turns 10 times slower than the input. This raises the result torque 10 times. Performance informs you how much power is shed inside the transmission via rubbing. Good gearboxes are extremely effective.

Lubrication is important. The majority of transmissions make use of oil baths. Some require oil. The appropriate lubricating substance type and level avoid wear and overheating. Examine and change lubricant as the manual states. Installing choices differ. Typical types are foot-mounted, flange-mounted, or shaft-mounted styles. Air conditioning may be required for high-power applications. Followers or water coats assist handle warm.

These gearboxes work in numerous areas. They drive conveyor belts in factories. They power mixers and pumps. Construction equipment relies on them. Agricultural devices use them as well. Wind wind turbines need durable gearboxes. Choosing the ideal gearbox implies checking lots, rate, environment, and duty cycle.

(Mechanical Transmission Gearbox)

Applications of Mechanical Transmission Gearbox

Mechanical transmission gearboxes are essential parts in lots of machines. They change the rate and torque coming from a power source like an engine or motor. This adjustment makes the power functional for various tasks. Gearboxes aid devices function successfully under various loads and rates.

Automotive applications rely greatly on transmissions. Cars and trucks and trucks utilize them to move engine power to the wheels. Hand-operated transmissions allow drivers choose gears. Automatic transmissions change gears without motorist input. Gearboxes regulate automobile speed and velocity. They provide the essential drawing power for pulling or climbing hillsides.

Industrial equipment makes use of transmissions frequently. Conveyor belts in factories rely on them for accurate rate control. Hefty equipment like cranes and excavators require transmissions for lifting hefty lots. Manufacturing makers make use of transmissions to drive reducing devices and production line. They make sure consistent operation and secure motors from pressure.

Power manufacturing utilizes transmissions too. Wind wind turbines transform slow blades blade rotation into high-speed generator rotation. Transmissions boost the rotational speed dramatically. This process produces electricity effectively. Other power generation devices frequently makes use of comparable transmission principles.

Marine propulsion systems integrate gearboxes. Boats and ships connect engines to props through them. Gearboxes take care of propeller rate and direction. They enable onward and reverse activity. They take care of the high torque needs of moving large vessels with water.

Aerospace applications need customized gearboxes. Airplane engines utilize gearboxes to drive accessories like fuel pumps. Helicopter blades systems depend on complicated gearboxes for lift and control. These gearboxes operate under extreme conditions. Integrity and weight are critical variables right here.

Construction devices uses robust transmissions. Excavators, loaders, and concrete mixers require them to move power to tracks or wheels. Transmissions supply the high torque needed for excavating and moving planet. They endure harsh environments and hefty influences daily.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Mechanical Transmission Gearbox

Mechanical Transmission Gearbox FAQs

What is a gearbox?

A gearbox changes speed and torque. It uses gears inside a case. Motors connect to it. It sends power to machines. This controls how fast things move and how much force they have.

Why use a gearbox?

Motors often spin too fast. They don’t have enough turning force. A gearbox fixes this. It reduces speed. It increases torque. Machines get the power they need. It protects the motor from strain.

What gearbox types exist?

Common types are parallel shaft, planetary, and right-angle. Parallel shaft gearboxes have gears side-by-side. They are simple and strong. Planetary gearboxes have gears around a central sun gear. They handle high power in small spaces. Right-angle gearboxes change the power direction 90 degrees. They save space.

How do I choose the right gearbox?

Think about your machine’s needs. Know the input speed. Know the torque required. Consider the operating environment. Is it hot, dirty, or wet? Match the gearbox size to your motor. Check the mounting style fits. Getting the specs right prevents early failure.

How do I maintain a gearbox?

Check the oil level regularly. Change the oil on schedule. Use the oil type the maker specifies. Listen for strange noises. Look for leaks. Feel for excess heat. Fix problems fast. Good maintenance makes gearboxes last much longer.

(Mechanical Transmission Gearbox)

REQUEST A QUOTE

RELATED PRODUCTS

Toyota hilux vigo pickup Transmission unit Gearbox assy for Toyota Hilux vigo pickup 33030-71200 3303071320 33019-71010

PLF Planetary Gearbox Motor Reducer Speed With Ratio 1:3 1:5 1:10 1:15 1:20 1:25 1:50 1:100

Hot Cheap Transmission Gearbox MR513BO1

0.06-15KW high efficiency R series screw reducer gearbox with motor flange can be used for industrial cement mixing

High Configuration Automatic Transmission Gearbox Factory Direct Whole New Condition Other Auto Systems